01

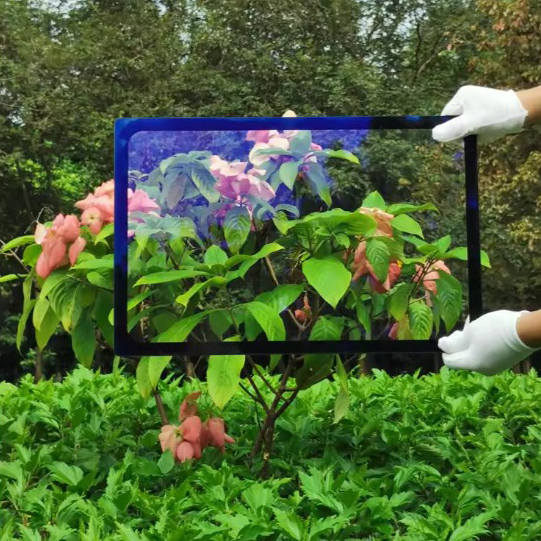

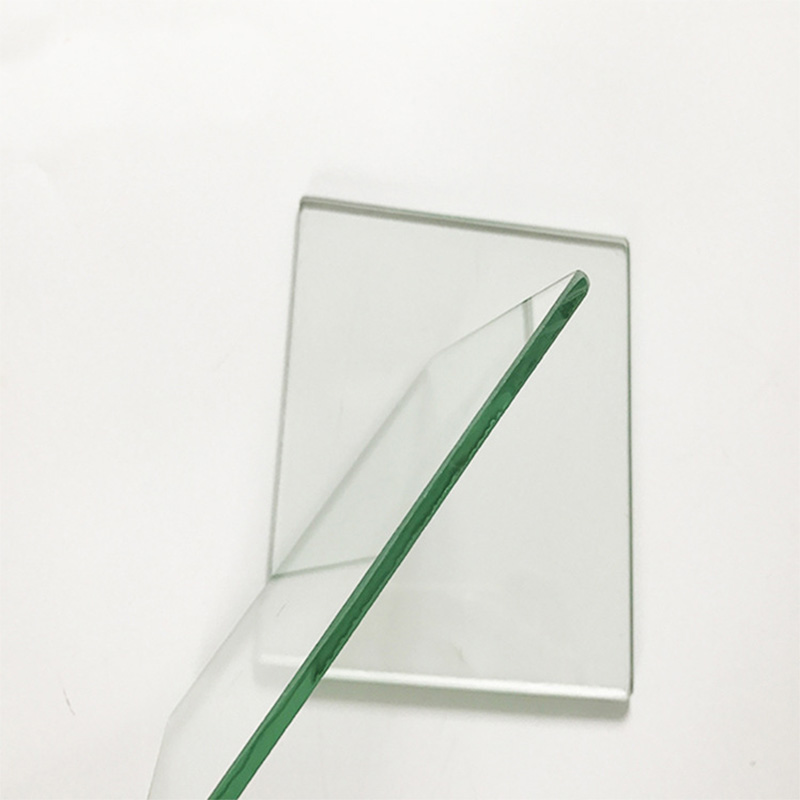

Transparent AF anti fingerprint coated glass factory

|

Mohs hardness |

7 |

|

Density |

5H |

|

Heat resistance |

1000 |

|

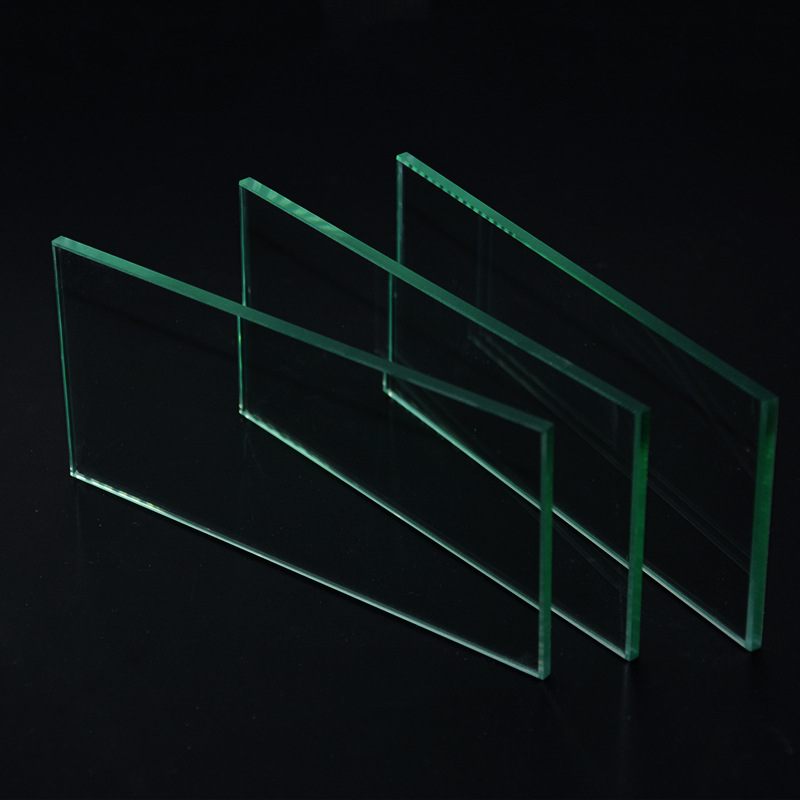

Color |

White Glass |

|

Production process |

CD |

|

Do you provide customized processing? |

Yes |

|

Printing LOGO |

Yes |

|

Specification and model |

Customized according to drawings |

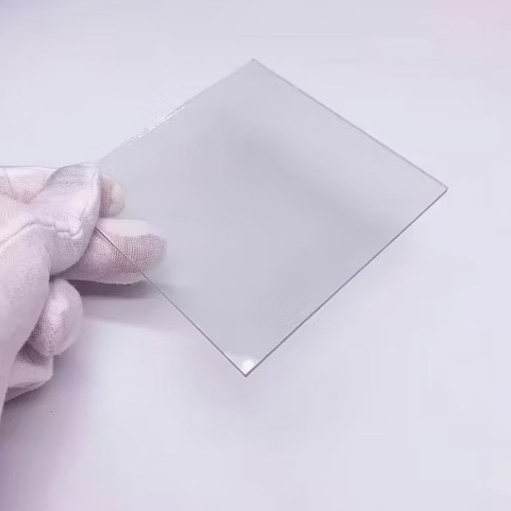

Coating Process and Inspection: The vacuum evaporation coating method is generally used, the SiO2 + AF materials (such as DON, M4, Dow Corning AF materials) coated on the glass surface, AF coating is mainly in the glass products through the optical vacuum coating equipment, in the vacuum state of the plating process, the uniformity of the AF anti-film layer and the adhesion of the glass on the good or bad will affect the product's waterproof, grease-proof, anti-fouling, anti-fingerprints of the human body effect, so usually after the completion of the AF coating process should be detected. Therefore, usually after the completion of the AF coating process should be tested on the product AF coating effect, the conventional method to detect the effect of AF is the drop angle test method, that is, the use of a test instrument, the liquid (generally pure water) drops on the surface of the solid, due to the role of the surface tension of the liquid, the liquid surface and the solid plane to form a certain angle between the tensor angle, through this angle to analyze the effect of the AF to determine!

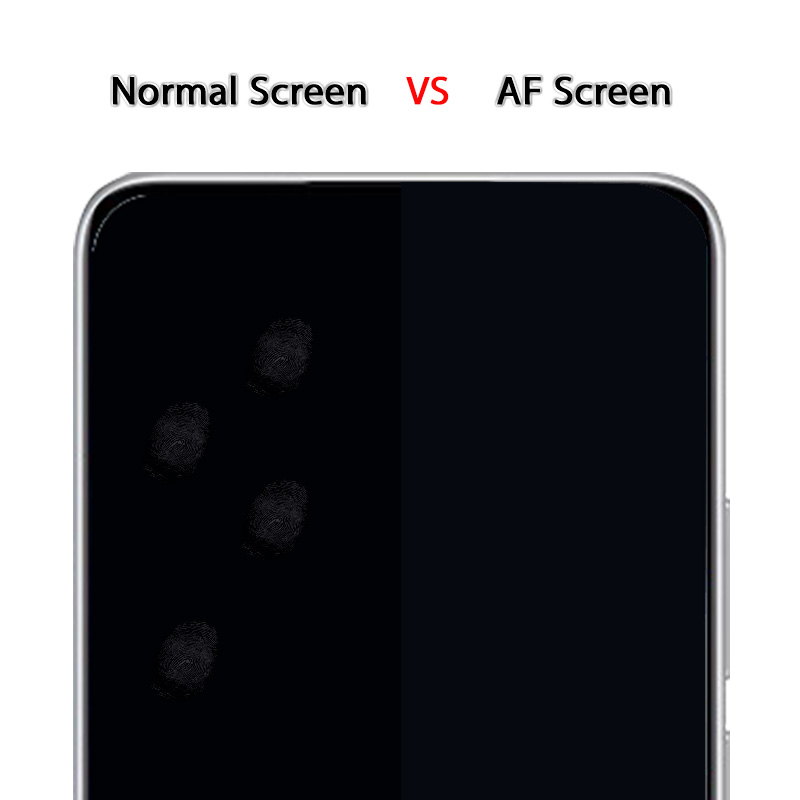

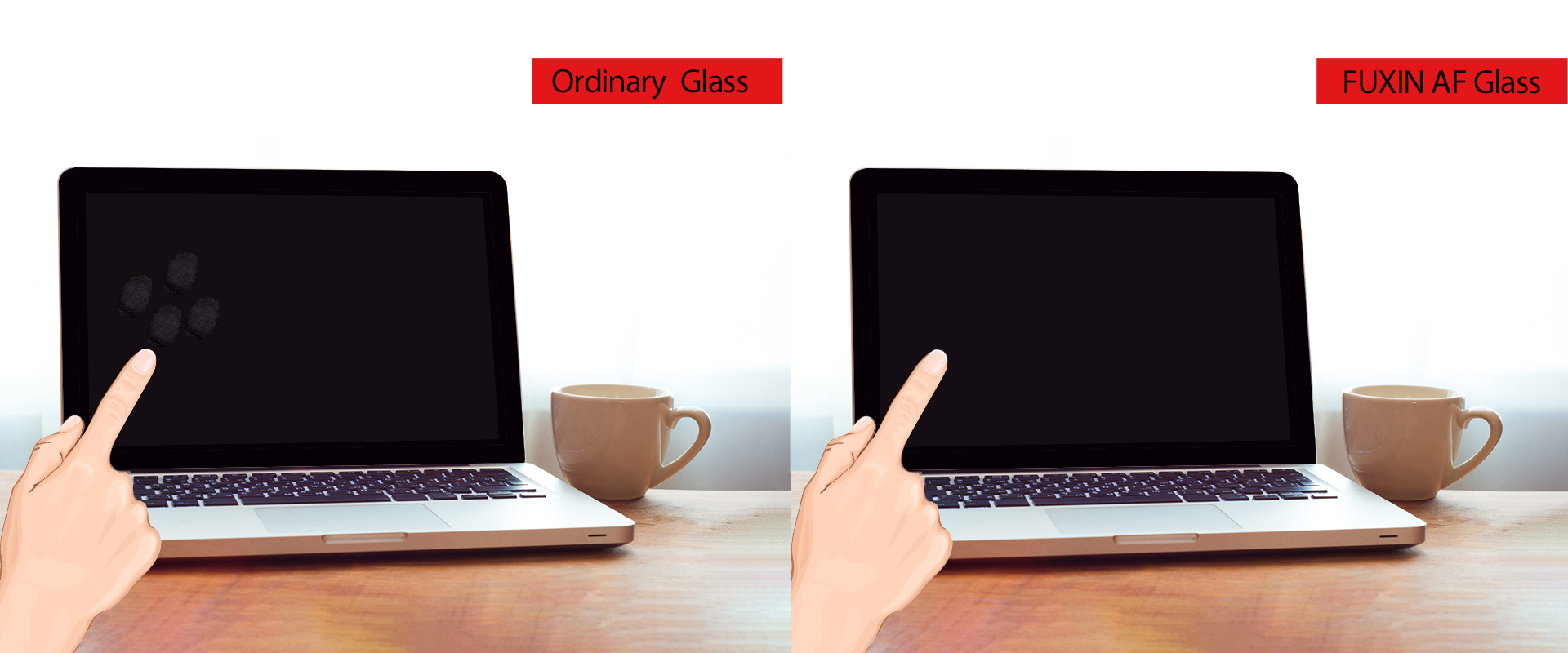

Application areas: Suitable for display glass covers on all touch screens, such as smartphones, tablets, and smart home touch all-in-one machines.

AF coating is single-sided and used on the front side of glass.

Application areas: Suitable for display glass covers on all touch screens, such as smartphones, tablets, and smart home touch all-in-one machines.

AF coating is single-sided and used on the front side of glass.