Unveiling the 7 Game-Changing Properties of Anti-Glare Cover Glass

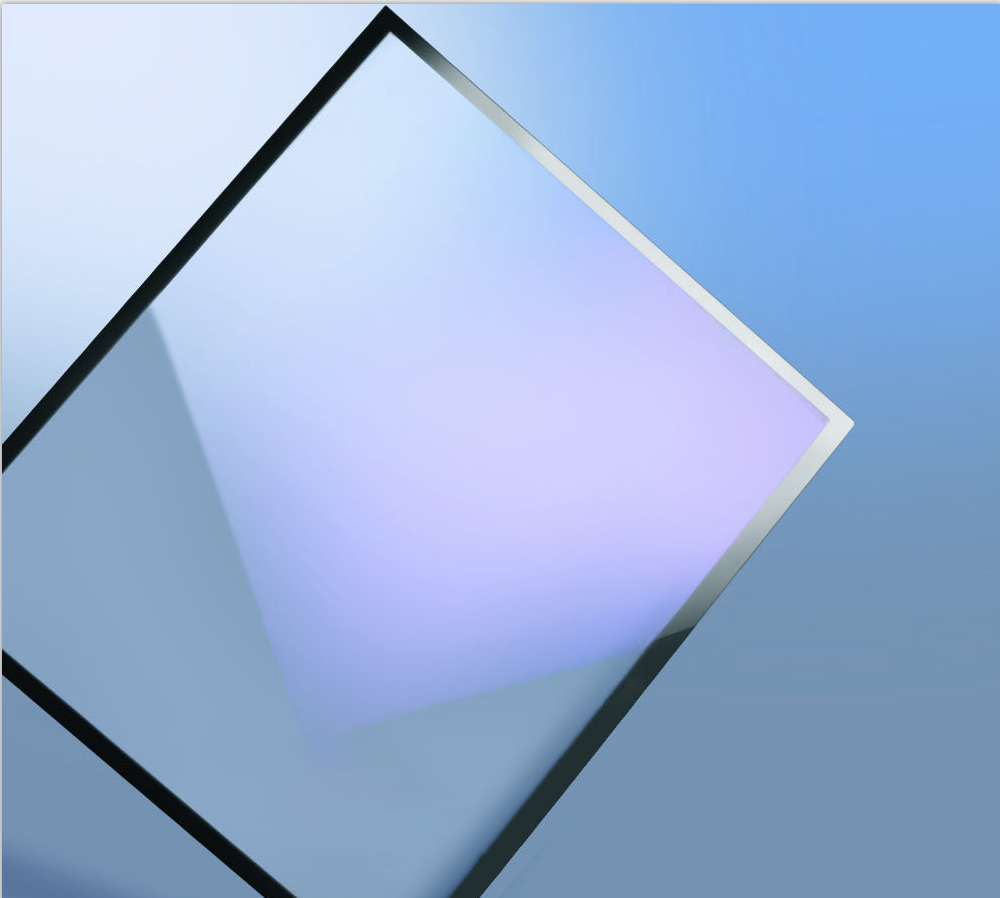

1. Advanced Anti-Reflection

AG glass utilizes nano-scale etching to scatter ambient light, reducing reflections by up to 75%. This technology ensures crisp visibility even under direct sunlight, eliminating the need for screen shielding.

2. Military-Grade Scratch Resistance

With surface hardness exceeding 9H (Mohs scale), our AG glass withstands daily abrasion from keys, coins, and industrial tools, maintaining optical integrity for years.

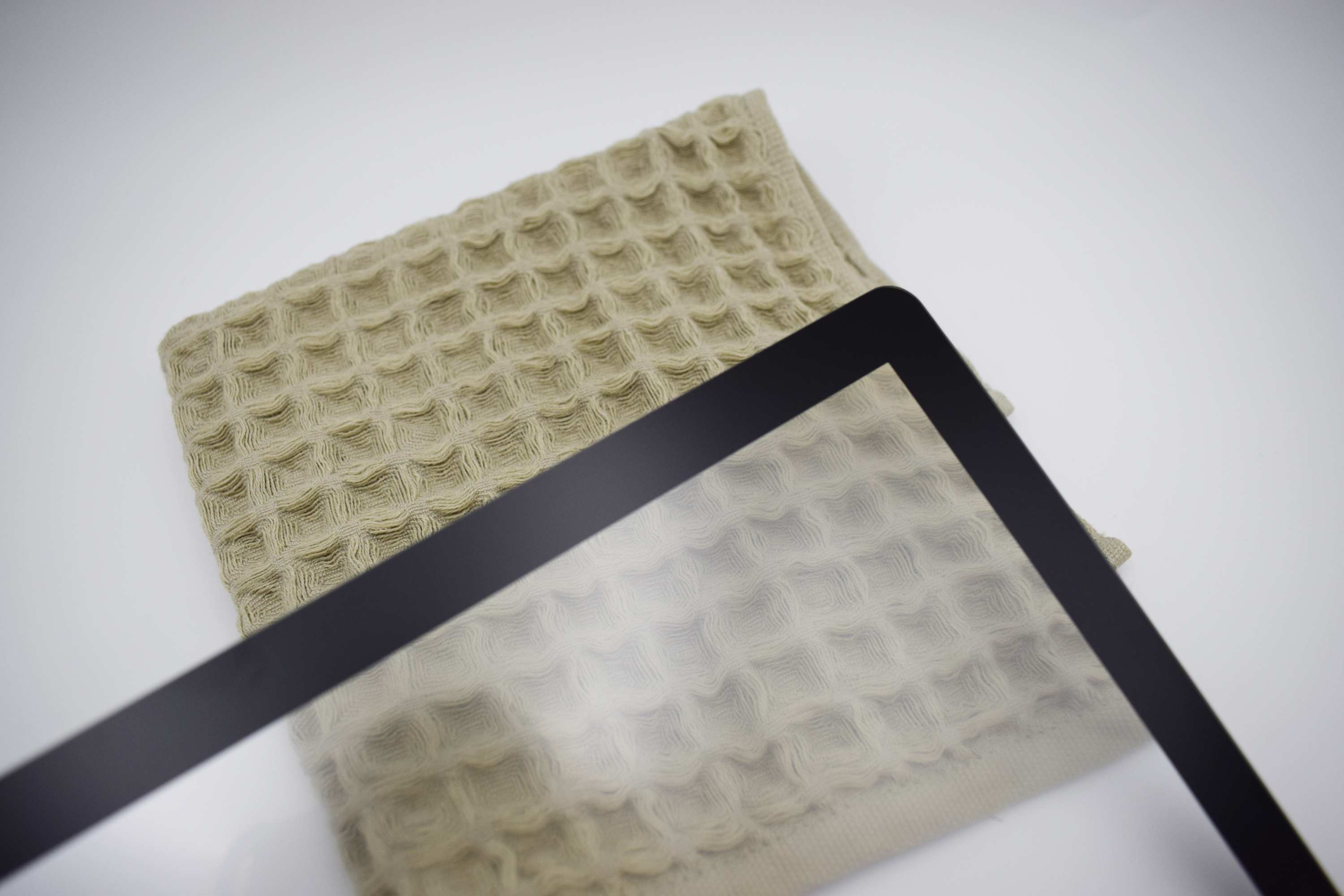

3. Silk-Touch Surface Texture

Proprietary coating creates a friction-optimized layer (Ra 0.1-0.3μm) that enables effortless touch gestures while resisting fingerprint smudges – a breakthrough for medical and public touchscreens.

4. 92%+ Light Transmission

Unlike conventional matte films, our AG glass preserves true color reproduction through precision surface engineering, critical for designers and photographers.

5. Chemical Armor Technology

Resists sweat, solvents, and UV degradation – proven through 1,000+ hours of QUV accelerated testing. Ideal for outdoor installations and high-humidity environments.

6. Hydro/Oleo-Phobic Fusion

Dual-layer nano-coating repels water and oils simultaneously, reducing cleaning frequency by 60% in high-traffic applications.

7. EMI Shielding Integration

Optional transparent conductive coatings block electromagnetic interference without compromising touch sensitivity – essential for aviation and military interfaces.

"AG glass is no longer just about reducing glare," notes Fuxin Glass CTO. "It's about creating self-maintaining surfaces that deliver perfect optical performance in the most demanding environments – from desert ATMs to oceanographic equipment."

Our AG solutions now protect over 3 million displays worldwide. Explore technical specifications and industry-specific solutions at Contact Us - Fuxin.