Unlocking Clarity: The Advanced Technology and Diverse Applications of AR Anti-Reflective Glass

Innovative Manufacturing: A Fusion of Surface and Bulk Engineering

The production of this dual-functional glass involves sophisticated processes at both the surface and material composition levels. For superior anti-reflective performance, advanced coating technologies are employed. These include patented plasma-assisted deposition methods, such as Plasma IAD (Ion-Assisted Deposition), which can create ultra-hard, climate-resistant AR layers on various polymers and glasses at temperatures below 100°C. Another frontier is the use of nano-technology to engineer porous microstructures that dramatically lower reflection. One breakthrough from China achieves a remarkable 99.7% light transmittance with a reflection rate as low as 1% by using a reverse micelle microsphere etching technique. For mass production, continuous vacuum coating processes have been developed, capable of coating large panels (up to 1500*1500mm) with a reflection rate under 0.3% in under four minutes.

The radiation shielding capability is engineered into the glass matrix itself. Researchers are developing novel glass compositions by doping with heavy metal oxides. For instance, doping lead borate glasses with Erbium Oxide (Er₂O₃) significantly enhances their density and radiation attenuation coefficients, outperforming conventional shielding materials. Similarly, incorporating Hafnium Oxide (HfO₂) into tellurite-based glasses drastically increases their linear attenuation coefficient for gamma rays. There is also a strong drive to develop effective lead-free alternatives, such as BaO-B₂O₃-TiO₂ ternary systems, which maintain high transparency while offering good radiation protection.

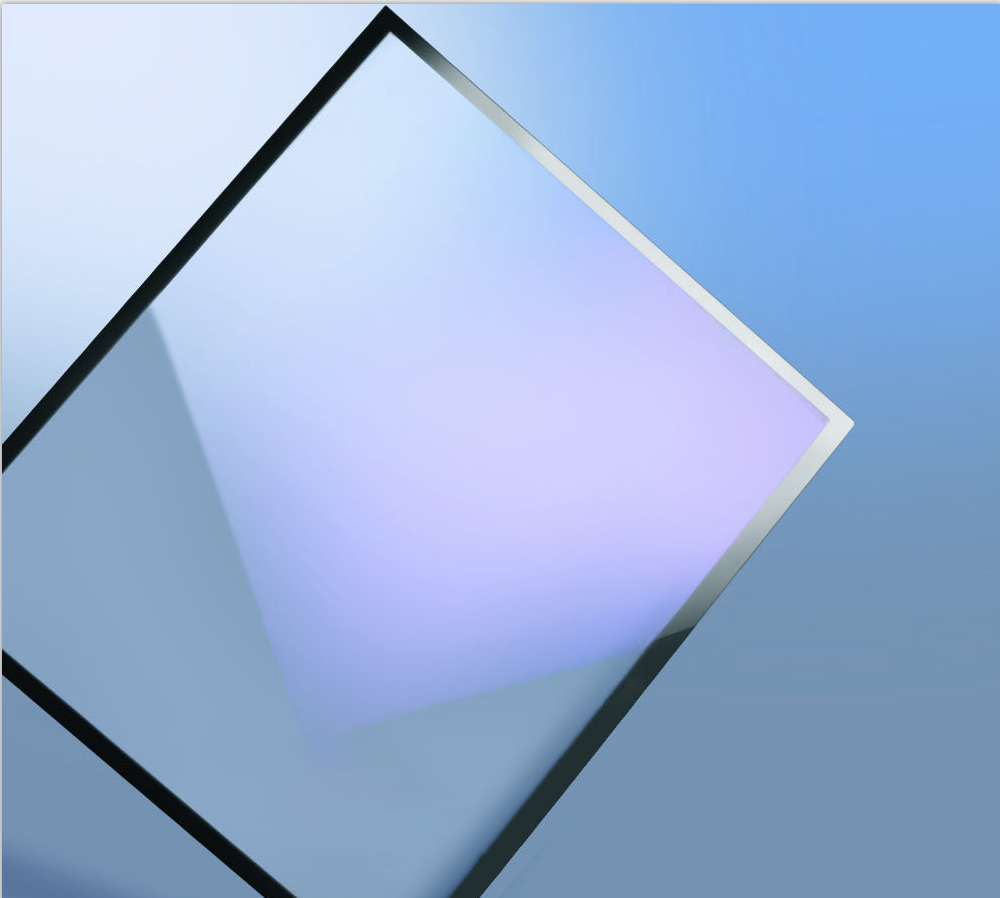

Dual-Action Benefits: Clarity Meets Protection

The primary function of this glass is twofold. First, it maximizes light transmission. High-performance AR coatings can boost the average visible light transmittance of glass to over 95%, with peak values reaching 99%, eliminating glare and reflection to deliver crystal-clear visuals. This is crucial for displays, sensors, and optical instruments. Second, it provides robust protection against harmful ionizing radiation (like X-rays and gamma rays). The specially designed glass composition acts as a barrier, absorbing and attenuating this radiation, thereby protecting sensitive electronics or human operators behind it.

Broad Spectrum of Critical Applications

The unique combination of properties opens doors to demanding applications:

-

Aerospace & Defense: Satellite components, spacecraft viewports, and optical sensors require materials that are both lightweight and can withstand cosmic radiation. Thin, flexible glass with anti-radiation properties, like those developed for China's space station solar wings, is a perfect example.

-

Nuclear & Medical Fields: Viewing windows for nuclear reactors, radiation therapy rooms, and diagnostic imaging equipment (like CT scanners) need transparent materials that shield against radiation. The developed Er₂O₃-doped or HfO₂-doped glasses are prime candidates for these roles.

-

High-Radiation Industrial & Research Environments: Optical systems in particle accelerators, nuclear fusion experiments, and industrial radiography benefit from lenses and windows that remain transparent while protecting downstream components.

-

Premium Consumer & Automotive Electronics: While focused on AR properties for glare reduction and scratch resistance (like the super-hard AR coating used in flagship smartphones), future devices used in specific environments could integrate baseline radiation shielding.

The convergence of nano-scale coating technology and advanced material science is creating a new paradigm in functional glass. This AR anti-radiation glass stands as a testament to innovation, addressing the growing need for materials that offer unparalleled optical performance without compromising safety and durability in the world's most challenging environments.