The Future is Clear: How Tempered Glass Mirrors Enhance Safety and Durability

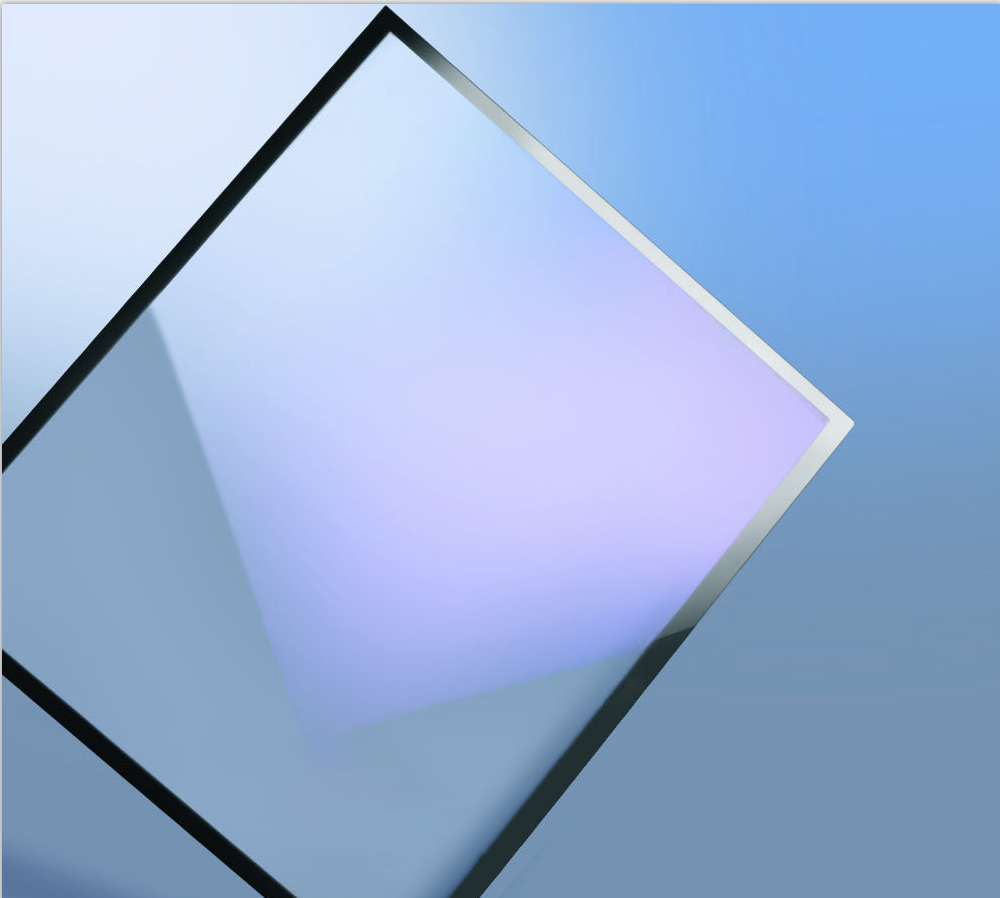

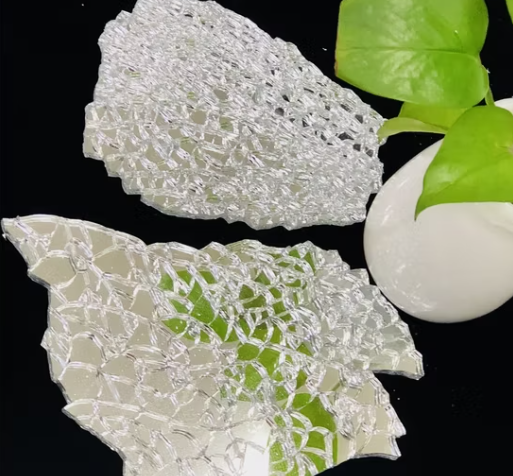

The fundamental principle involves heating the glass to over 600°C and then rapidly cooling it. This process creates a surface compression layer, making the glass 4-5 times stronger than its standard counterpart. The most critical safety feature is its breakage pattern; when shattered, it crumbles into small, granular pieces instead of dangerous, sharp shards.

The manufacturing process is precise. It begins with cutting high-quality glass to size, followed by meticulous edge grinding. The glass is then heated in a specialized furnace and undergoes rapid, controlled air quenching. This is typically done after the reflective coating is applied, ensuring the mirror's optical clarity and integrity are preserved.

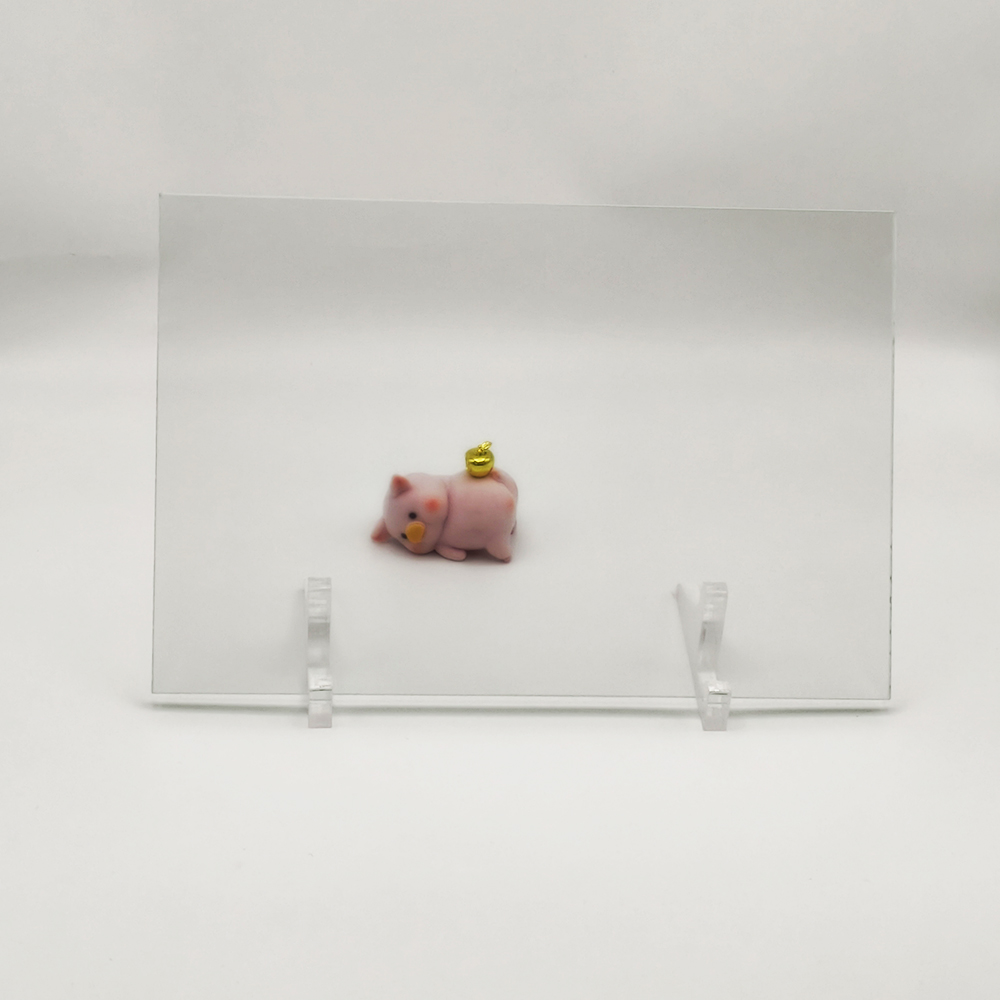

Tempered glass mirrors have diverse applications. They are essential in architecture and interiors for bathrooms, hotels, and public spaces where user safety is a concern. The industrial sector utilizes them as durable sight glasses in equipment and for machinery where impact resistance is needed. Furthermore, they are increasingly specified for commercial fixtures like furniture and fitness centers, combining functionality with paramount safety.

Boost Your Project's Safety and Quality

Upgrade to our certified tempered glass mirrors for unmatched durability and peace of mind. Contact us today for a quote and discover our custom solutions.