Float Glass: The Clear Choice for Premium Electronic Display Covers

The Principle of Float Glass: Where Precision Meets Innovation

Float glass is manufactured by melting raw materials such as silica sand, soda ash, and dolomite at high temperatures. The molten glass is then poured onto a bed of molten tin, where it floats and spreads evenly, forming a smooth, flat surface. This process, known as the "float method," ensures uniform thickness and exceptional surface quality, free from distortions or waves. The result is a pristine glass ribbon that cools gradually before being cut into sheets—a foundational step for high-quality display covers.

The Manufacturing Process: From Molten Glass to Flawless Panels

-

Raw Material Fusion: Precise proportions of silica, calcium oxide, and magnesium are melted in a furnace at ~1550°C.

-

Floating on Tin: The glass flows onto molten tin, creating a perfectly level surface. The non-reactive nature of tin prevents contamination, ensuring optical purity.

-

Annealing and Cooling: The glass undergoes controlled cooling to relieve internal stresses, enhancing durability.

-

Cutting and Quality Control: The cooled glass is trimmed to size, with strict checks for dimensional accuracy and defects.

For display cover glass, additional steps like chemical strengthening (e.g., ion exchange in potassium nitrate) boost scratch and impact resistance.

Key Parameters for Display Cover Glass Applications

When selecting float glass for electronic displays, consider these critical parameters:

-

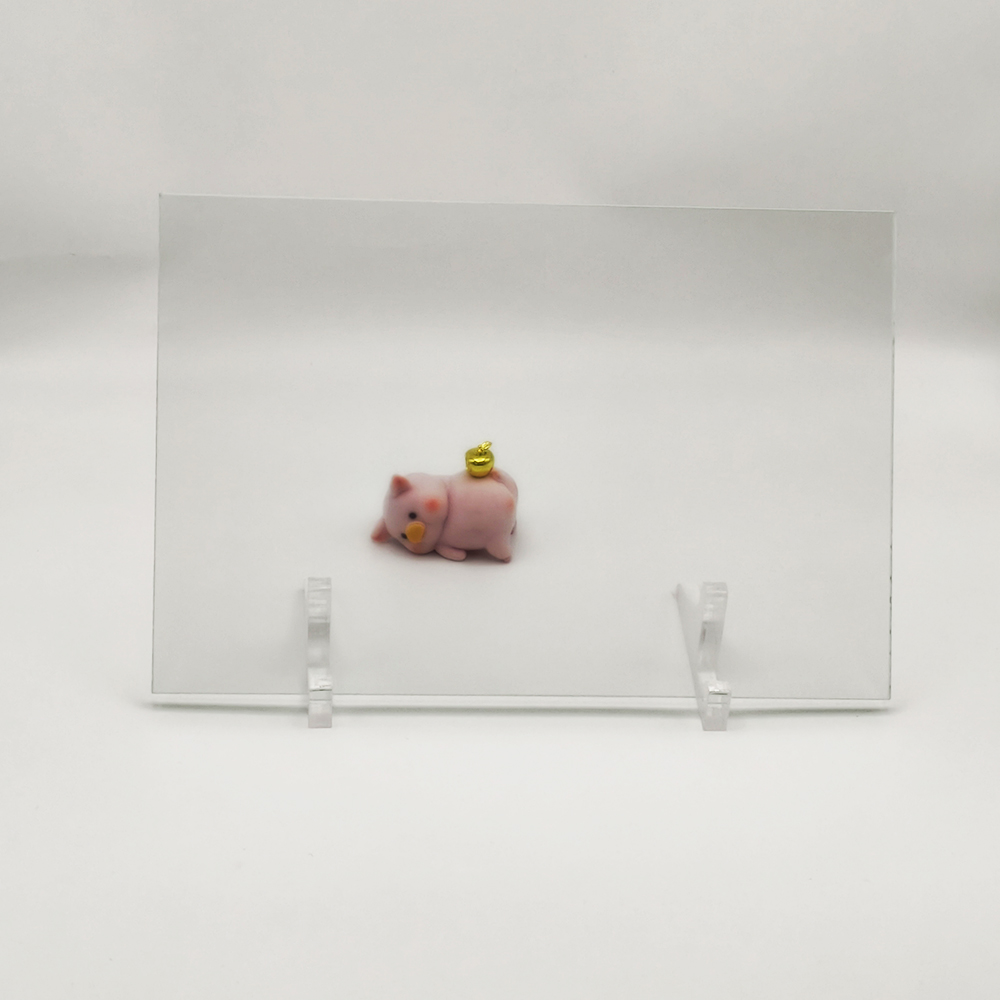

Surface Flatness: Essential for touch sensitivity and visual clarity. Float glass achieves a distortion-free surface ideal for high-resolution screens.

-

Thickness Tolerance: Ultra-thin variants (≤1.10 mm), as per GB/T 20314-2017 standards, are suited for LCDs and portable devices.

-

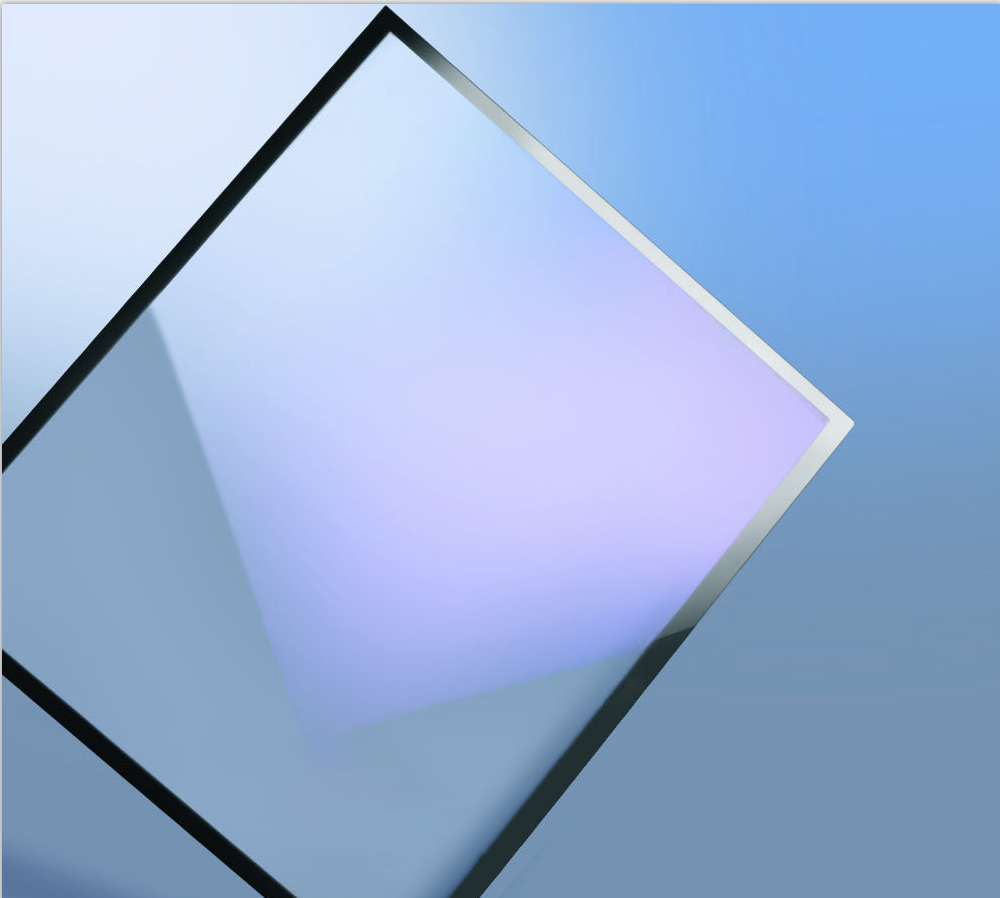

Optical Properties: Low-iron formulations minimize greenish tints, providing superior color accuracy for displays.

-

Mechanical Strength: Chemically strengthened glass resists daily wear, with stress layers tailored to device requirements.

Why Choose Float Glass for Display Covers?

-

Versatility: From sodium-calcium glass for cost-sensitive applications to high-performance aluminosilicate glass (e.g., Gorilla Glass®), float glass adapts to diverse needs.

-

Cost-Effectiveness: Sodium-calcium float glass offers a balance of affordability and functionality, while low-iron versions deliver premium aesthetics.

-

Industry Compliance: Float glass meets international standards for thin glass in LCDs, OLEDs, and emerging technologies like Quantum Dot displays.

Selection Guide: Matching Glass to Your Product

-

Budget-Friendly Displays: Sodium-calcium float glass (e.g., for industrial touchscreens).

-

Mid-Range Devices: Low-iron float glass for color-critical displays like tablets.

-

High-End Electronics: Aluminosilicate glass (via overflow fusion) for superior strength and flexibility in smartphones.

Future Trends: Innovating with Float Glass

As displays evolve toward foldable and energy-efficient designs, float glass remains at the forefront. Its role in substrates for OLEDs and protective covers for Mini-LEDs underscores its versatility. By partnering with suppliers who master float glass parameters, brands can leverage this material to create thinner, brighter, and more resilient devices.

Unlock Your Display's Potential

From prototyping to mass production, float glass offers a reliable path to exceptional display performance. Explore our curated range of float glass solutions tailored to electronic covers, and connect with our experts for personalized guidance.

Contact us today to request a sample or discuss your project requirements!