Beyond Protection: How Advanced Cover Glass Technologies Empower Touchscreen Durability & Clarity

1. The Evolution: From Basic Shield to Interactive Core

Cover glass has transformed from a passive protector to an active interface enabler. Key milestones include:

-

2007 Revolution: Corning Gorilla Glass enabled touch-sensitive smartphone screens, replacing fragile plastic panels

-

2.5D/3D Breakthroughs: Edge-curved glass (R0.5-R8mm radius) enhanced ergonomics, with 3D variants using hot-bending at 800°C to achieve complex shapes for VR headsets and automotive displays

-

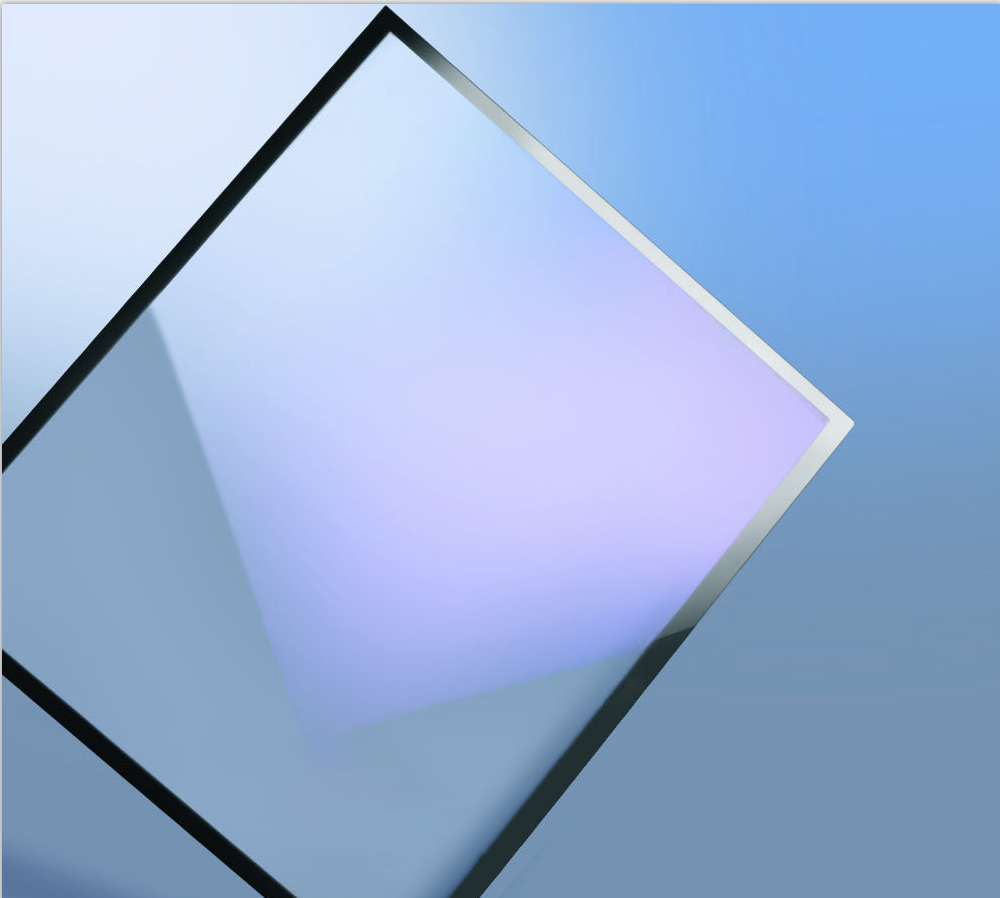

Functional Integration: Modern cover glass integrates anti-glare (AG), anti-reflective (AR), and anti-fingerprint (AF) coatings directly during manufacturing

2. Critical Manufacturing Processes Explained

① Surface Engineering: The Armor Layer

-

Nano-Crystal Coatings: Biel Crystal's "Magic Cloak" technology stacks 4,000+ micro-crystal layers, achieving 15x scratch resistance and SGS 5-star certification

-

Ion Exchange Strengthening: Glass submerged in molten potassium nitrate creates compressive stress up to 850 MPa (vs. 600 MPa industry avg), boosting drop resistance

② 3D Forming: Precision Thermal sculpting

-

Hot-Bending Challenges: Heating to 800°C requires exact control—rapid cooling causes micro-cracks, while slow cycles reduce throughput

-

Laser Cutting Innovation: Biel's post-bending laser edge processing eliminates chipping, enabling Apple Vision Pro's seamless curvature

3. Future Frontiers: Where Cover Glass is Headed

-

Self-Healing Glass: Nano-coatings that repair scratches within 24 hours (lab prototype stage)

-

Dynamic 4D Glass: Shape-shifting surfaces for foldable devices, with Samsung/Apple patents pending

-

Eco-Tempering: New energy-efficient strengthening processes reducing carbon footprint by 45%

-

Antibacterial Integration: Silver-ion infused glass for medical and public touchscreens

Engineer the Unbreakable with Our Expertise! Welcome to request Custom Coating Samples (AG/AR/AF + Antibacterial Options)