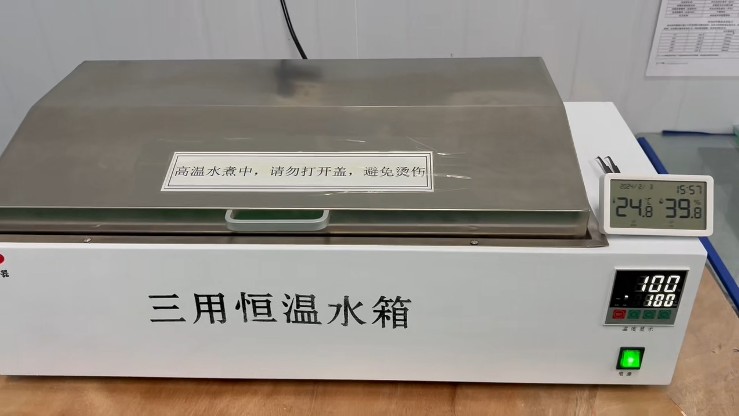

AG Cover Glass Excellence Validated Through Rigorous Boil Testing

The Critical Challenge: Why Boil Testing Matters

For manufacturers of high-end appliances, automotive interiors, and premium consumer electronics, component failure is not an option. Laminated glass panels, in particular, are susceptible to degradation when exposed to heat and moisture over time. The primary risk is delamination and bubble formation within the interlayer, which compromises optical clarity, structural integrity, and product safety.

Standardized tests like the ASTM C 1914 (Standard Test Method for Bake and Boil Testing of Laminated Glass) are employed globally to quantitatively measure this laminate stability under controlled, extreme conditions. Passing this test is a non-negotiable benchmark for any glass destined for environments where reliability is critical.

Our Test Protocol: Rigor Beyond Standards

Our evaluation process is designed to simulate years of accelerated environmental stress. The testing followed a meticulously controlled protocol, adhering to core principles of boil testing:

-

Test Standard: Conducted with reference to ASTM C 1914 methodology.

-

Conditions: Samples were fully immersed in deionized water at 100°C to prevent mineral interference.

-

Duration: Subjected to extended cycles, far exceeding basic quality checks, to evaluate long-term performance.

-

Assessment: Post-test analysis included visual inspection for bubbles, haze, or delamination and measurements of optical property retention

Results That Define Excellence

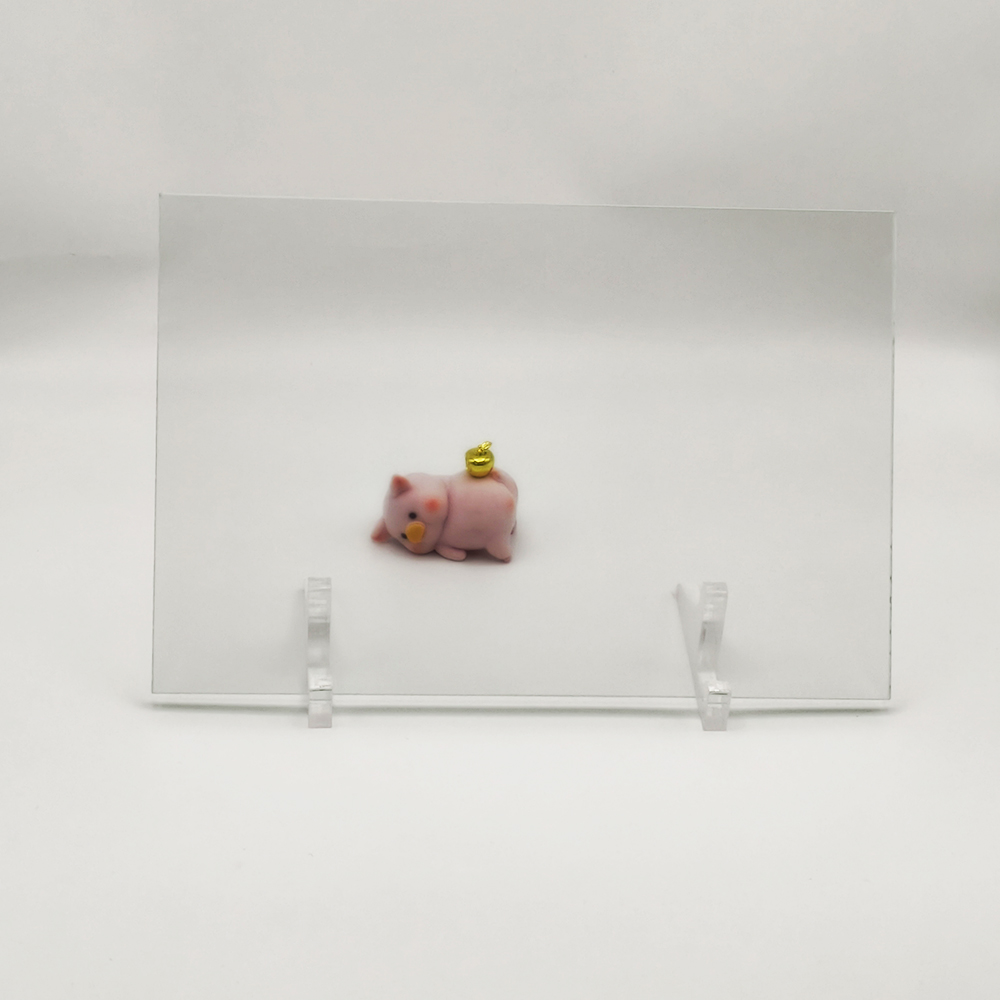

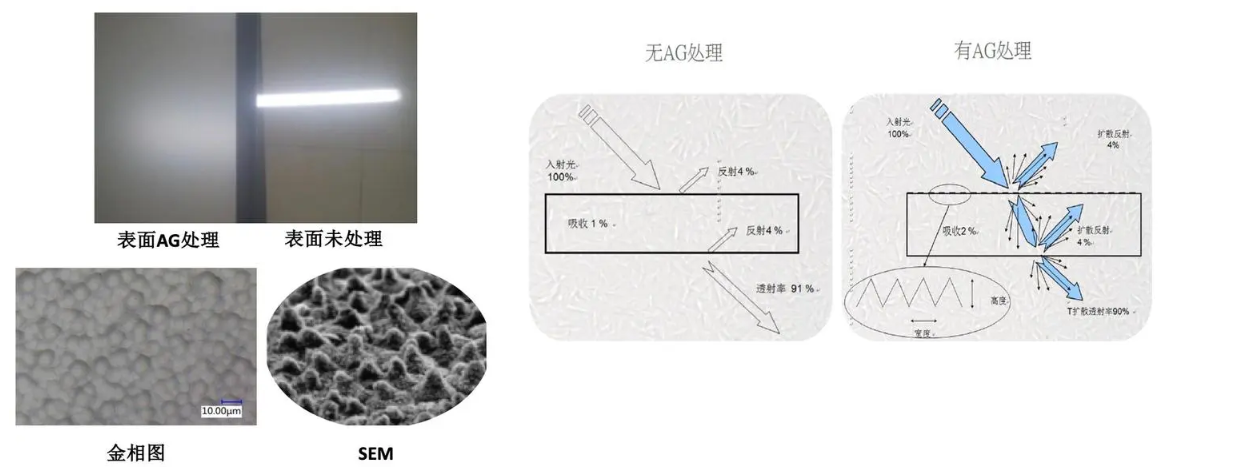

Post-test evaluation confirmed our AG glass's superior engineering. The samples exhibited:

-

Zero Delamination: No bubbles or cloudiness formed at the glass-interlayer interface.

-

Optical Integrity Uncompromised: The anti-glare properties and light transmission values remained stable.

-

Structural Integrity Maintained: No warping, softening, or loss of mechanical strength was observed.

This performance is rooted in our material science. Unlike ordinary soda-lime glass, which can only withstand thermal shocks of about 50°C, our treated glass is engineered for robustness. The AG etching process is performed on high-quality, thermally strengthened glass, creating a surface that is both highly durable and resistant to scratches and chemicals.

Commercial Implications for Buyers and Designers

For procurement managers, product designers, and quality assurance teams, these results translate into tangible benefits:

-

Reduced Failure Rates: Minimize costly returns, warranties, and reputation damage from field failures.

-

Extended Product Lifespan: Ideal for devices requiring long-term reliability in kitchens (appliances), vehicles (center consoles), or outdoor settings.

-

Simplified Compliance: Eases the path to meeting stringent international safety and quality standards for various markets.

-

Design Confidence: Enables the creation of more innovative and reliable products with the assurance of a proven component.

About Fuxin Glass

Founded in 2012, Fuxin Glass is a leading manufacturer specializing in the research, development, production, and export of cover glass, headquartered in Dongguan, China, near the ports of Shenzhen and Guangzhou.

With 13 years of industry experience, Fuxin serves customers in over 80 countries worldwide. With ISO/RoHS/JIS Z certifications, Fuxin Glass is dedicated to providing high-quality glass solutions for electronic displays and smart devices. Its products are widely used in interactive display, automotive electronics, industrial equipment, medical devices, home appliances, and smart devices. The products feature high light transmittance (over 95%), high hardness (Mohs 6), and excellent scratch and impact resistance. The 21,000-square-meter factory is equipped with four fully automated production lines, with a monthly production capacity of 300,000 pcs. We support small-batch trial production and large-scale delivery, and provide one-step technical support and after-sales service. Multi-dimensional customization is supported as well: including but not limited to mold design (samples can be produced in as fast as 7 days), special optical processing (AR/AF/AG/AM combination), explosion-proof structure design (multi-layer composite structure), color customization (7 colors are optional), silk screen logo, etc., to meet the personalized needs of customers. Our products have successfully entered mainstream markets such as North America, Japan, South Korea, India, and Europe, and widely serve interactive ( such us all in one machine, IFPD, smart white board ), automotive central control screens, industrial HMI, smart home panels and other fields.

Welcome to inquiry!