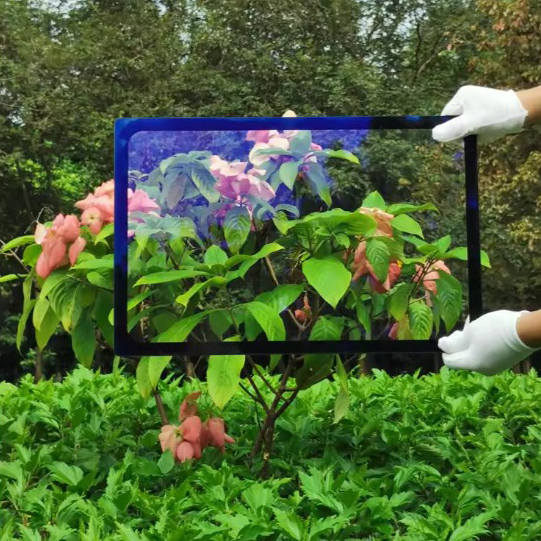

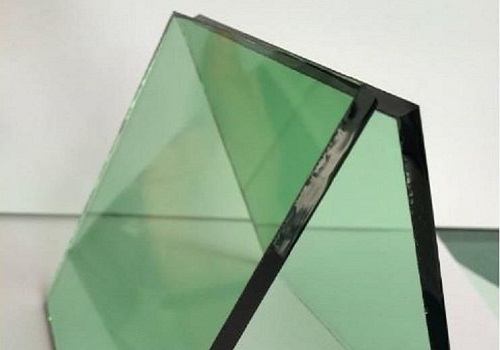

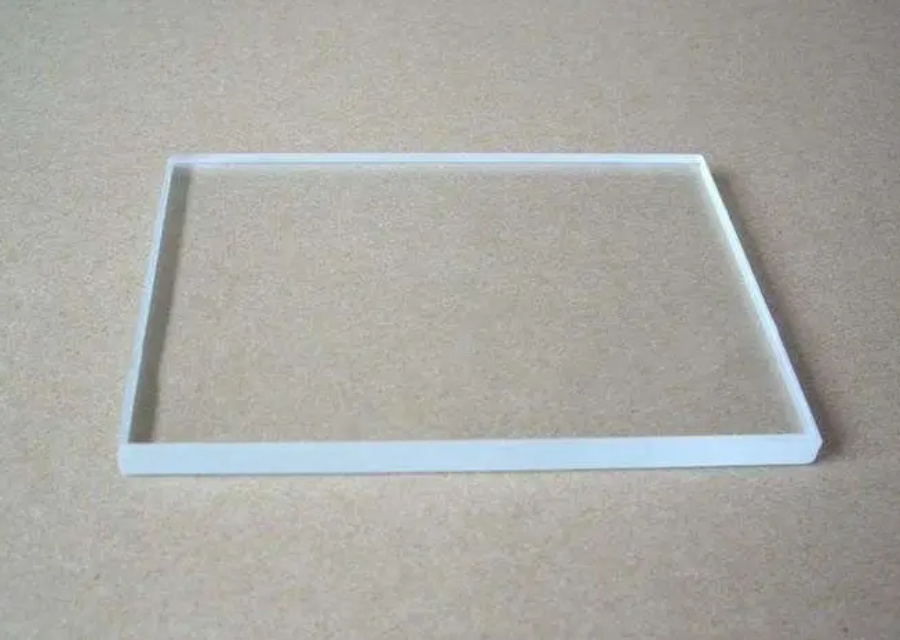

Premium AG Anti-Glare Glass for Display Screens - Reduce Glare, Enhance Visibility

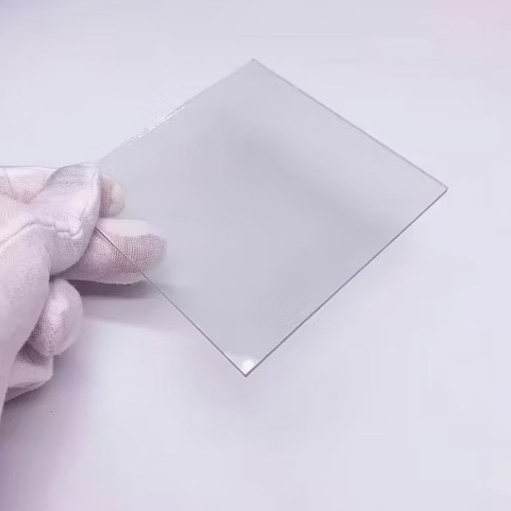

Optional Glass Materials for AG Anti-Glare Cover Glass

-

Soda-Lime Glass: A cost-effective and widely used option. Ideal for applications where high impact resistance is not the primary concern, such as indoor displays and touch panels.

-

Aluminosilicate Glass: Offers superior mechanical strength, scratch resistance, and durability compared to soda-lime glass. It is chemically strengthened to withstand higher levels of impact and stress, making it perfect for demanding applications like automotive displays and industrial control panels.

-

Lithium-Aluminosilicate Glass (Chemically Strengthened): This premium option provides the highest level of performance. It can be chemically strengthened to achieve exceptional surface compression, resulting in superior drop and impact resistance. It is the ideal choice for high-end, lightweight, and durable devices requiring maximum protection.

Key Technical Parameters for AG (Anti-Glare) Glass Cover Panels

Application Scenarios for AG Anti-Glare Glass

AG Anti-Glare glass is essential for displays that require optimal readability in various lighting conditions. Its primary application areas include:

-

Consumer Electronics: Used in tablets, laptops, monitors, and gaming devices to reduce eye strain and improve screen clarity in brightly lit homes and offices.

-

Automotive: Ideal for dashboard displays, center consoles, and heads-up displays (HUDs) to minimize sunlight and overhead light reflections, ensuring critical driving information is always visible.

-

Medical Equipment: Critical for surgical monitors, diagnostic imaging screens, and patient monitors in sterile, brightly lit hospital environments, where precise color and detail are vital.

-

Industrial & HMIs: Protects touchscreens on factory floor machines, ATMs, kiosks, and point-of-sale (POS) systems from glare under harsh lighting, while offering durability against scratches and frequent use.

-

Public & Outdoor Displays: Enhances visibility for digital signage, information kiosks, and outdoor advertising screens, combating direct sunlight and ambient indoor lighting for clear content viewing.

Company Introduction

Founded in 2012, Fuxin Glass is a leading manufacturer specializing in the research, development, production, and export of cover glass, headquartered in Dongguan, China, near the ports of Shenzhen and Guangzhou.

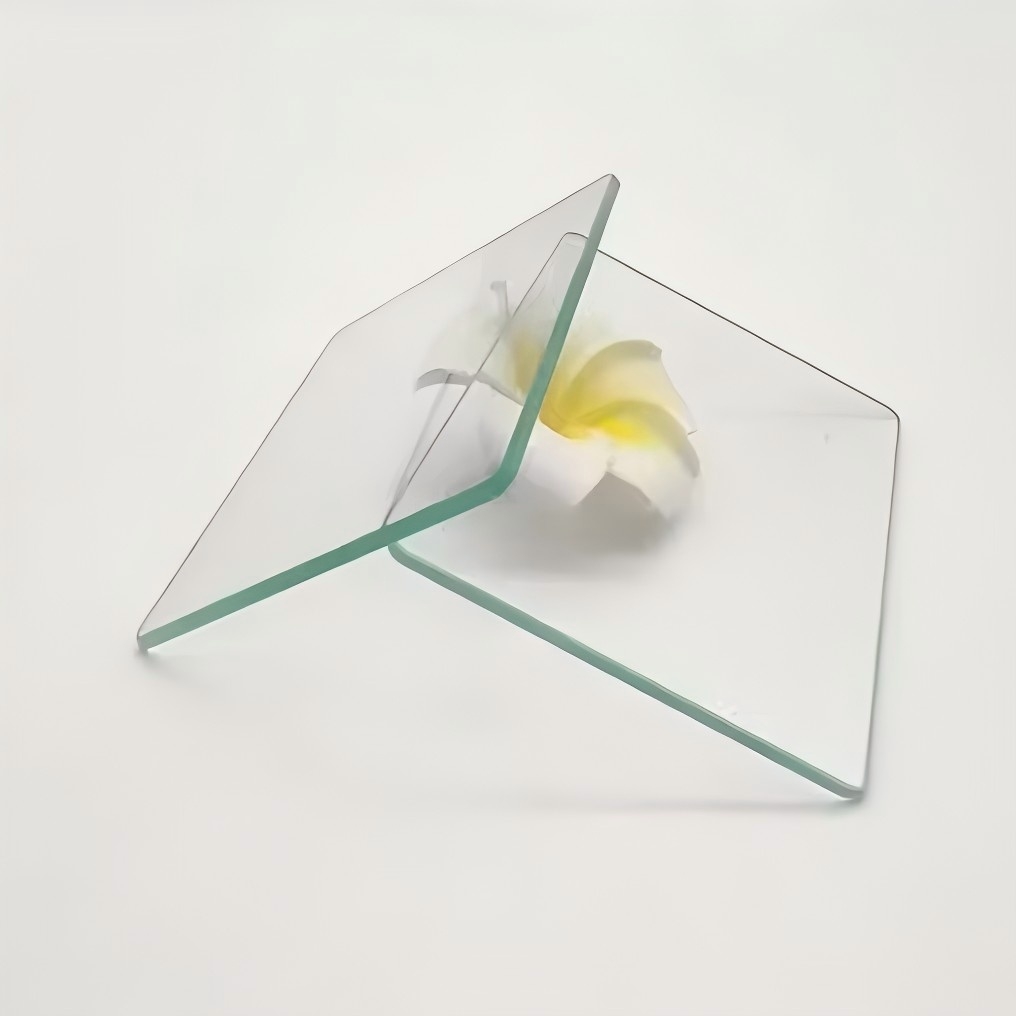

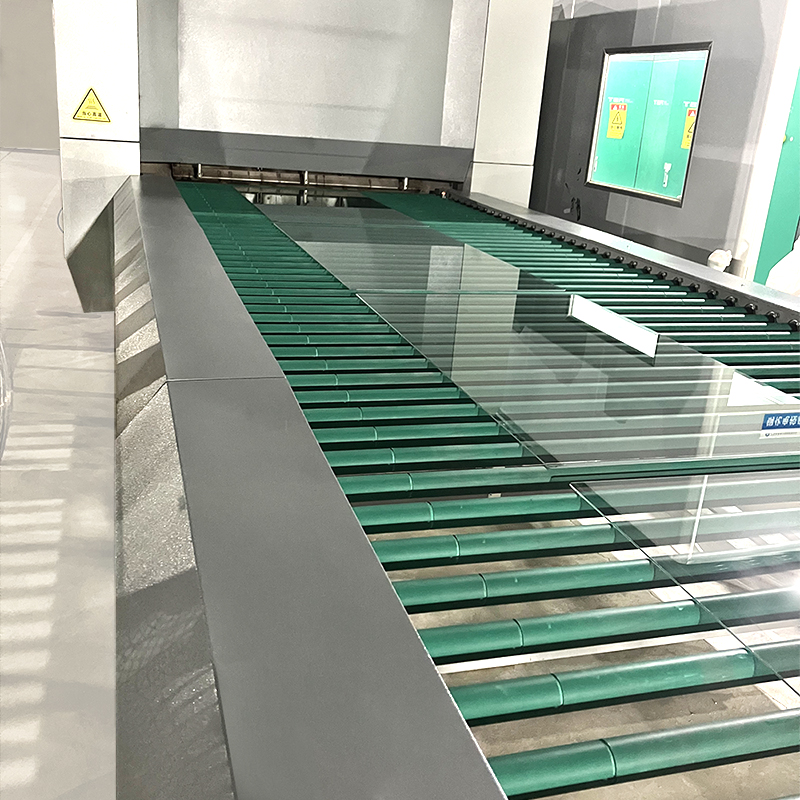

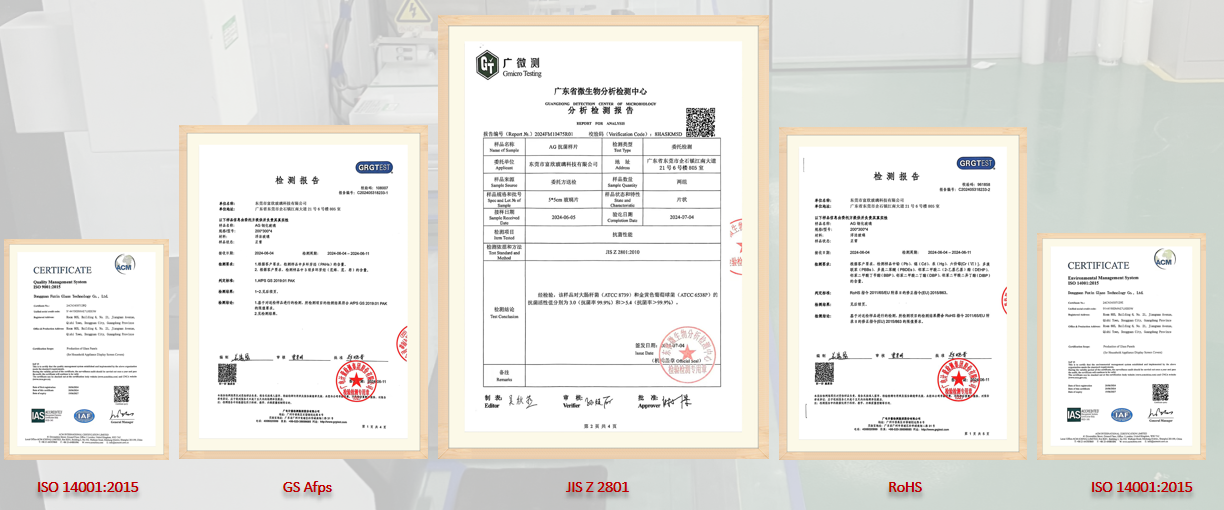

With 13 years of industry experience, Fuxin serves customers in over 80 countries worldwide. With ISO/RoHS/JIS Z certifications, Fuxin Glass is dedicated to providing high-quality glass solutions for electronic displays and smart devices. Its products are widely used in interactive display, automotive electronics, industrial equipment, medical devices, home appliances, and smart devices. The products feature high light transmittance (over 95%), high hardness (Mohs 6), and excellent scratch and impact resistance. The 21,000-square-meter factory is equipped with four fully automated production lines, with a monthly production capacity of 300,000 pcs. We support small-batch trial production and large-scale delivery, and provide one-step technical support and after-sales service. Multi-dimensional customization is supported as well: including but not limited to mold design (samples can be produced in as fast as 7 days), special optical processing (AR/AF/AG/AM combination), explosion-proof structure design (multi-layer composite structure), color customization (7 colors are optional), silk screen logo, etc., to meet the personalized needs of customers. Our products have successfully entered mainstream markets such as North America, Japan, South Korea, India, and Europe, and widely serve interactive ( such us all in one machine, IFPD, smart white board ), automotive central control screens, industrial HMI, smart home panels and other fields.

We always adhere to the principle of "integrity, quality and win-win" and are willing to establish good long-term cooperative relationships with customers all over the world!

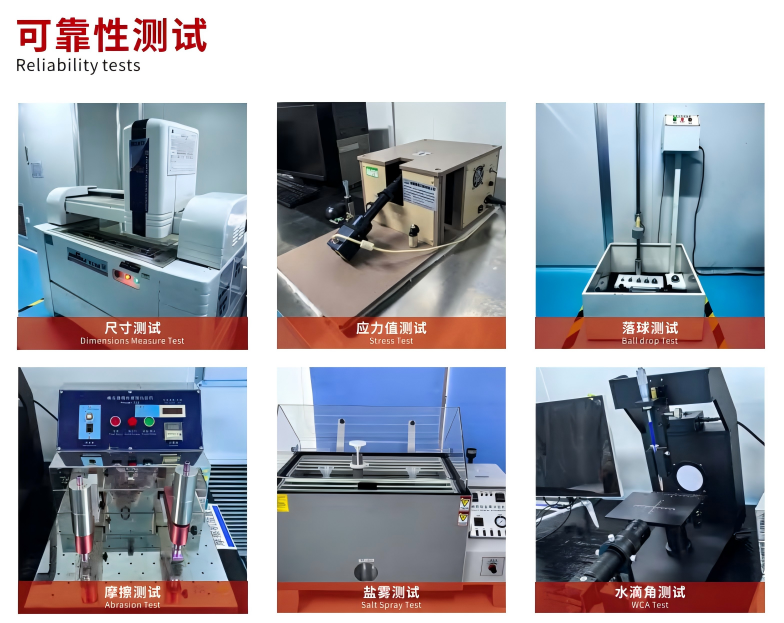

Inspection Progress

Factory Overview

Certification

Package

Delivery & Lead Time

| Original Country | China |

| FOB Port | Shenzhen or Hongkong |

| HS Code | 700719000 |

| Lead Time | Sample within 7 days, bulk order 15~20 days |

| Delivery | By sea / DHL / Fedex / UPS |

Payment Details

1. Soda-lime Glass (Ordinary Flat Glass)

- Composition: Mainly composed of silicon dioxide (SiO₂, approximately 70%), sodium oxide (Na₂O), and calcium oxide (CaO).

- Characteristics: Easy to produce, low cost, but poor thermal stability and brittle.

- Applications: The most common type of glass, used for doors, windows, bottles, jars, and everyday utensils.

2. Borosilicate Glass (Heat-Resistant Glass)

- Composition: Based on soda-lime glass, boron oxide (B₂O₃) is added.

- Characteristics: Low coefficient of thermal expansion, high temperature resistance, resistance to rapid temperature changes (not easily cracked by sudden heating and cooling), good chemical stability.

- Applications: Laboratory instruments (such as beakers and test tubes), heat-resistant tableware (such as baking pans and glass pots), high-end flashlight lenses, etc. Well-known brands include Pyrex.

3. Aluminosilicate Glass

- Composition: Contains a large amount of aluminum oxide (Al₂O₃) and silicon dioxide (SiO₂).

- Characteristics: High hardness, scratch resistance, high mechanical strength, superior performance compared to borosilicate glass.

- Applications: Cover glass for high-end mobile phones/tablets, aviation glass, etc. Well-known brands include Corning Gorilla Glass.

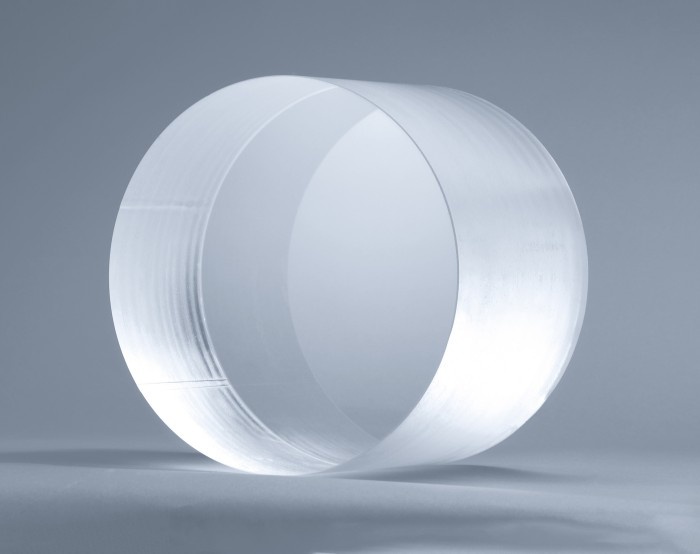

4. Quartz Glass

- Composition: Silicon dioxide (SiO₂) content is above 99%.

- Characteristics: Excellent heat resistance (softening point up to 1700℃), wide light transmission spectrum (from ultraviolet to infrared), high purity, and excellent chemical stability. However, it is expensive.

- Applications: Semiconductor industry, optical devices, observation windows in high-temperature furnaces, ultraviolet lamps, etc.

To get an accurate quotation, please provide (if available):

- Product dimensions & glass thickness

- Application / usage

- Edge grinding type

- Surface treatment (coating - AG/AR/AF/AM or overlay, printing, etc.)

- Packaging requirements

- Quantity or annual usage

- Required delivery time

- Drilling or special hole requirements

- Drawings or photos

If you don't have all the details yet: just provide the information you have. Our team can discuss your requirements and help you determine specifications or suggest suitable options.

-

1

1) Are you a trading company or manufacturer?

1. Leading glass deep processing factory

2. 13 years of experience

3. OEM/ODM expertise -

2

2) How to order?

1. Your detailed requirements: drawings/quantity/or your special requirements.

2. Let's get to know each other better: We can provide your requirements.

3. Email us your formal order, payment.

4. We will incorporate the order into our mass production plan and produce according to the approved sample.

5. Packing & shipping -

3

3) Do you provide samples for testing?

We can provide free samples, but the shipping cost will be borne by the customer.

-

4

4) What is your minimum order quantity?

A: 200 pieces.

-

5

5) How long does a sample order take? How about a bulk order?

Sample order: Usually within a week.

Bulk order: Usually takes 15~20 days depending on quantity and design. -

6

6) What packaging do the products use?

Plastic wrap + pearl cotton + kraft paper + cartoon box + wooden crate.

-

7

7) How do you ship the goods, and how long does it take to arrive?

We usually ship by sea / air freight/ International Express, and the arrival time depends on the distance.

-

8

8) What are your payment terms?

A: T/T 100% in advance, or other payment methods.

-

9

9) Do you provide OEM/ODM services?

Yes, we can customize.

-

9

10) Do your products have certificates?

Yes, we have ISO9001/REACH/RoSH/GS/JIS Z certifications.