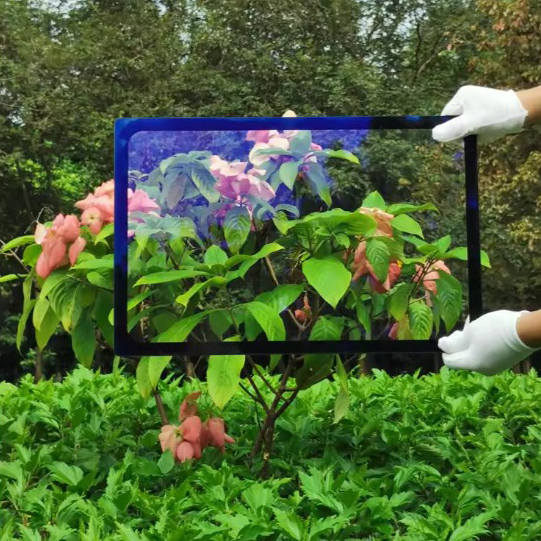

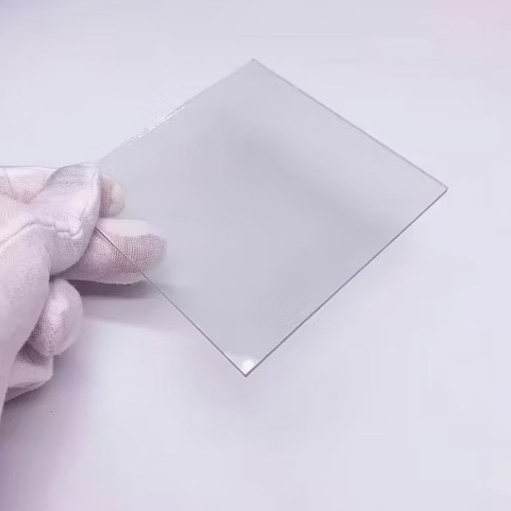

Premium Customized 1.1mm Touchscreen Cover Glass- AG & AR Surface Treatment with High Transmittance

Company Introduction

Founded in 2012, Fuxin Glass is a leading manufacturer specializing in the research, development, production, and export of cover glass, headquartered in Dongguan, China, near the ports of Shenzhen and Guangzhou.

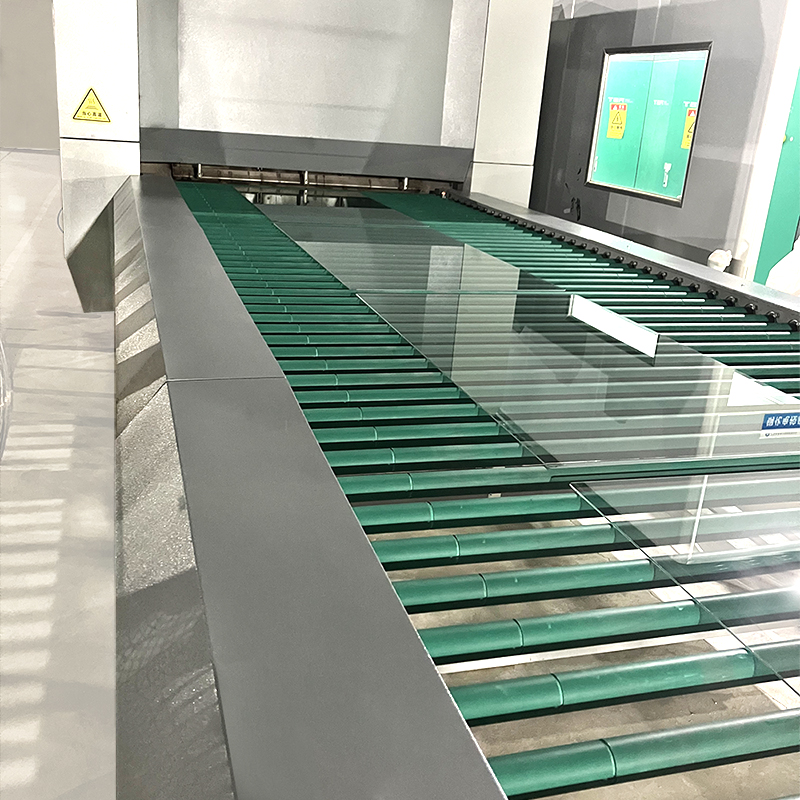

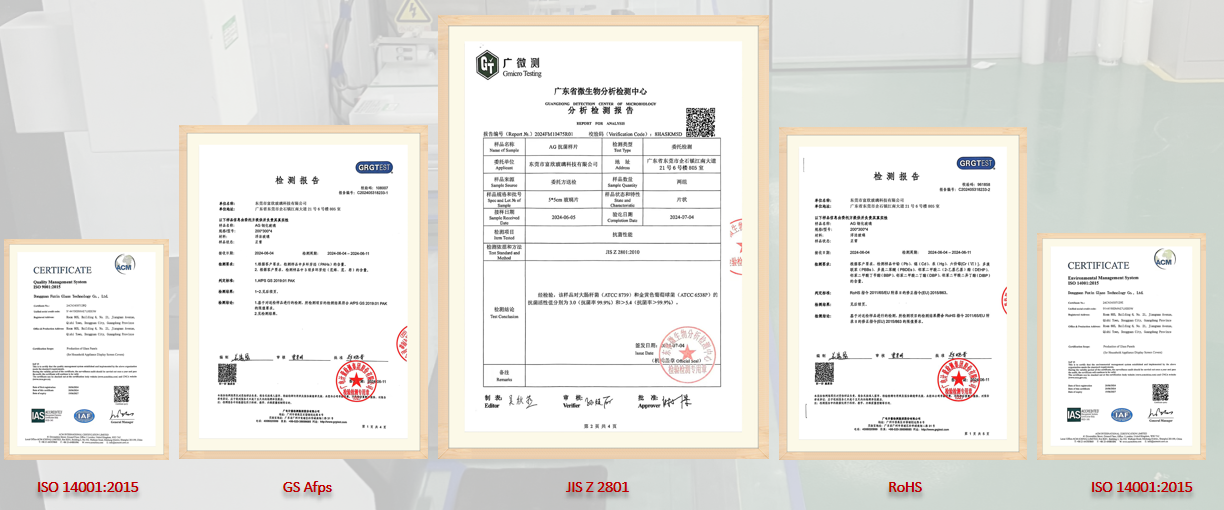

With 13 years of industry experience, Fuxin serves customers in over 80 countries worldwide. With ISO/RoHS/JIS Z certifications, Fuxin Glass is dedicated to providing high-quality glass solutions for electronic displays and smart devices. Its products are widely used in interactive display, automotive electronics, industrial equipment, medical devices, home appliances, and smart devices. The products feature high light transmittance (over 95%), high hardness (Mohs 6), and excellent scratch and impact resistance. The 21,000-square-meter factory is equipped with four fully automated production lines, with a monthly production capacity of 300,000 pcs. We support small-batch trial production and large-scale delivery, and provide one-step technical support and after-sales service. Multi-dimensional customization is supported as well: including but not limited to mold design (samples can be produced in as fast as 7 days), special optical processing (AR/AF/AG/AM combination), explosion-proof structure design (multi-layer composite structure), color customization (7 colors are optional), silk screen logo, etc., to meet the personalized needs of customers. Our products have successfully entered mainstream markets such as North America, Japan, South Korea, India, and Europe, and widely serve interactive ( such us all in one machine, IFPD, smart white board ), automotive central control screens, industrial HMI, smart home panels and other fields.

We always adhere to the principle of "integrity, quality and win-win" and are willing to establish good long-term cooperative relationships with customers all over the world!

Inspection Progress

Factory Overview

Certification

Package

Delivery & Lead Time

| Original Country | China |

| FOB Port | Shenzhen or Hongkong |

| HS Code | 700719000 |

| Lead Time | Sample within 7 days, bulk order 15~20 days |

| Delivery | By sea / DHL / Fedex / UPS |

Payment Details

1) Classification by Main Chemical Composition (The Most Basic Classification Method)

This is the most fundamental classification method, determining the basic physical and chemical properties of glass.

1. Soda-lime Glass (Ordinary Flat Glass)

- Composition: Mainly composed of silicon dioxide (SiO₂, approximately 70%), sodium oxide (Na₂O), and calcium oxide (CaO).

- Characteristics: Easy to produce, low cost, but poor thermal stability and brittle.

- Applications: The most common type of glass, used for doors, windows, bottles, jars, and everyday utensils.

2. Borosilicate Glass (Heat-Resistant Glass)

- Composition: Based on soda-lime glass, boron oxide (B₂O₃) is added.

- Characteristics: Low coefficient of thermal expansion, high temperature resistance, resistance to rapid temperature changes (not easily cracked by sudden heating and cooling), good chemical stability.

- Applications: Laboratory instruments (such as beakers and test tubes), heat-resistant tableware (such as baking pans and glass pots), high-end flashlight lenses, etc. Well-known brands include Pyrex.

3. Aluminosilicate Glass

- Composition: Contains a large amount of aluminum oxide (Al₂O₃) and silicon dioxide (SiO₂).

- Characteristics: High hardness, scratch resistance, high mechanical strength, superior performance compared to borosilicate glass.

- Applications: Cover glass for high-end mobile phones/tablets, aviation glass, etc. Well-known brands include Corning Gorilla Glass.

4. Quartz Glass

- Composition: Silicon dioxide (SiO₂) content is above 99%.

- Characteristics: Excellent heat resistance (softening point up to 1700℃), wide light transmission spectrum (from ultraviolet to infrared), high purity, and excellent chemical stability. However, it is expensive.

- Applications: Semiconductor industry, optical devices, observation windows in high-temperature furnaces, ultraviolet lamps, etc.

5. Lead Crystal Glass

- Composition: Lead oxide (PbO) replaces calcium oxide, and sometimes potassium oxide (K₂O) is added.

- Features: High refractive index, high specific gravity, produces a clear metallic sound when struck, easy to carve and cut, and appears dazzling.

- Applications: High-end art pieces, crystal chandeliers, wine glasses, decorative items.

2) Classification by Composition and Optical Properties:

Clear Glass: Formal name: Ordinary float glass / Clear glass; refers to: the most common type of transparent flat glass.

Characteristics:

Color: Under natural light, it appears slightly greenish when viewed from the side or edge. This is due to trace amounts of iron impurities in its raw materials.

Light transmittance: Relatively low, typically between 84% and 89% (for a 6mm thickness).

Cost: Lowest production cost, making it the most widely used type of glass.

Applications:

Architectural doors and windows: The most common type of window glass.

Furniture: Glass doors for items such as bookcases and wardrobes.

Daily utensils: Some common glass cups and plates.

Glass substrate: Used as a base sheet in the manufacture of tempered glass, insulated glass, laminated glass, etc.

Ultra-clear Glass: Formal name: Low-iron glass / High-transparency glass; refers to: a high-quality, highly transparent glass.

Characteristics:

Color: As transparent as crystal, with almost no green tint when viewed from any angle. This is because its raw materials are carefully selected, resulting in extremely low iron content.

Light transmittance: Extremely high, typically exceeding 91% (for a 6mm thickness), providing a visual experience far superior to clear glass.

Self-explosion rate: Due to fewer internal impurities, its tempered glass has a much lower self-explosion rate than ordinary clear glass.

Cost: High production costs; the price is typically 2-4 times or even higher than ordinary clear glass.

Applications: High-end building curtain walls and skylights: For modern buildings seeking ultimate transparency and aesthetic appeal.

High-end furniture and display cases: For display cases in museums and luxury stores, providing the most accurate representation of the objects' true colors.

Solar photovoltaics: The cover glass for solar cells requires extremely high light transmittance to ensure power generation efficiency.

Aquariums: Large fish tanks, ensuring a clear and undistorted viewing experience.

3) Classification by Manufacturing Process and Functional Characteristics (Common Classifications in Daily Life)

This classification, based on the basic components, uses different processing techniques to give glass special properties.

1. Flat Glass

Float Glass: The most mainstream modern flat glass production process, where molten glass floats on the surface of molten tin to form the glass. The surface is smooth and flat, without ripples.

Tempered Glass (Safety Glass): Through heat treatment, compressive stress is formed on the glass surface, greatly increasing its strength. When broken, it forms small particles, reducing the risk of injury.

Laminated Glass (Safety Glass): An organic polymer interlayer (such as PVB) is sandwiched between two or more panes of glass. Upon impact, fragments adhere to the interlayer, preventing penetration and shard splashing. Commonly used in car windshields and bank windows.

Insulating Glass: Two or more panes of glass are evenly separated by effective supports and sealed around the edges, creating a dry gas space between the layers. It has excellent heat and sound insulation properties. Used in building doors, windows, and curtain walls.

Coated Glass: Glass with one or more layers of metal/compound thin film coated on its surface to alter its optical properties.

Heat-Reflective Glass: Reflects solar energy for building energy conservation.

Low-E Glass (Low-E Glass): Coated with a low-emissivity film, allowing visible light to pass through but reflecting far-infrared rays, providing excellent thermal insulation.

2. Deep-Processed and Specialty Glasses

Fire-Resistant Glass: Maintains its integrity and heat insulation for a certain period, preventing the spread of fire. Divided into composite fire-resistant glass (with a special transparent fire-resistant adhesive) and monolayer cesium potassium fire-resistant glass.

Bulletproof Glass: Actually a type of laminated glass, made of multiple panes of glass and high-grade PC sheets, capable of withstanding bullet impact.

Microcrystalline Glass: Glass containing a large number of microcrystals, produced through controlled crystallization. Combining the properties of glass and ceramics, it boasts high strength, thermal shock resistance, and an adjustable coefficient of thermal expansion. Used in induction cooker panels, astronomical telescope blanks, chemical pipelines, etc.

Smart Glass: The transparency and opacity of the glass are controlled by applying electricity (electrochromic/polymer-dispersed liquid crystal) or light (photochromic). Used for privacy protection, projection screens, etc.

Glazed Glass: A layer of colored fusible glaze is coated on the glass surface, and heat treatment is used to firmly bond the glaze to the glass. It has decorative properties and is resistant to chemical corrosion.

4) Classification by Appearance and Artistic Effect

These types of glass are mainly used in decorative and artistic fields.

Patterned Glass: Before the glass hardens, patterns are pressed onto one or both sides of the glass using rollers with engraved designs. It is translucent but not transparent, possessing decorative qualities.

Frosted Glass: The glass surface is roughened using mechanical sandblasting or chemical methods, causing diffuse reflection of light and achieving a translucent but not transparent effect.

Enameled Glass: Similar to enamel glass, it is an important building decoration material.

Inlaid Glass: Made by splicing together glass sheets of various colors and textures with metal strips, it is often used for retro-style doors and windows and decorative paintings.

Laser-Engraved Glass: Using a laser to create micro-cracks inside the glass, forming a predetermined three-dimensional pattern, it is crystal clear and highly artistic.

-

1

1) Are you a trading company or manufacturer?

1. Leading glass deep processing factory

2. 13 years of experience

3. OEM/ODM expertise -

2

2) How to order?

1. Your detailed requirements: drawings/quantity/or your special requirements.

2. Let's get to know each other better: We can provide your requirements.

3. Email us your formal order, payment.

4. We will incorporate the order into our mass production plan and produce according to the approved sample.

5. Packing & shipping -

3

3) Do you provide samples for testing?

We can provide free samples, but the shipping cost will be borne by the customer.

-

4

4) What is your minimum order quantity?

A: 200 pieces.

-

5

5) How long does a sample order take? How about a bulk order?

Sample order: Usually within a week.

Bulk order: Usually takes 15~20 days depending on quantity and design. -

6

6) What packaging do the products use?

Plastic wrap + pearl cotton + kraft paper + cartoon box + wooden crate.

-

7

7) How do you ship the goods, and how long does it take to arrive?

We usually ship by sea / air freight/ International Express, and the arrival time depends on the distance.

-

8

8) What are your payment terms?

A: T/T 100% in advance, or other payment methods.

-

9

9) Do you provide OEM/ODM services?

Yes, we can customize.

-

9

10) Do your products have certificates?

Yes, we have ISO9001/REACH/RoSH/GS/JIS Z certifications.