Display Cover Glass

Products |

Display Cover Glass |

Glass Material |

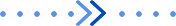

Soda-lime Glass,Aluminosilicate Glass,Low Iron Glass,Borosilicate Glass |

Size |

Customizable size (10.1-110) |

Thickness |

0.5-6 mm |

Tempered |

Physical Tempering,Chemical tempering |

Edge Treatment |

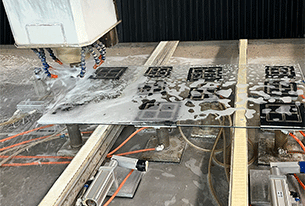

CNC Grinding, Polishing, Chamfering |

Hole |

Round,Square (irregular holes available) |

Color |

Black,White,Silver (up to 7 layers of color) |

Printing Method |

Ordinary Screen Printing,High Temperature Screen Printing |

Coating |

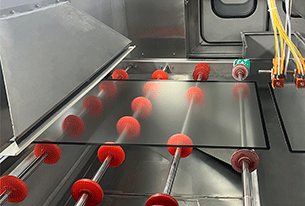

Anti-glare,Anti-reflection,Anti-fingerprint,Anti-scratch,Anti-bacterial |

Production Process |

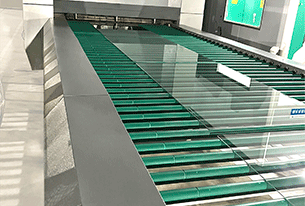

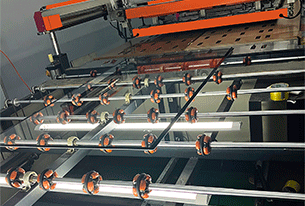

Coating-Cutting-Edging--Cleaning-Tempered-Printing |

Features |

Anti-scratch,Waterproof,Anti-fingerprint,Fireproof,Easy to Clean,High Pressure Scratch Resistance,Anti-glare,Anti-bacterial,High anti-reflection |

Origin |

China |

Shape |

Flat-panel |

Packaging |

Protective Film and Safety Packaging |

After-sales Service |

Returns and Exchanges |

Usage |

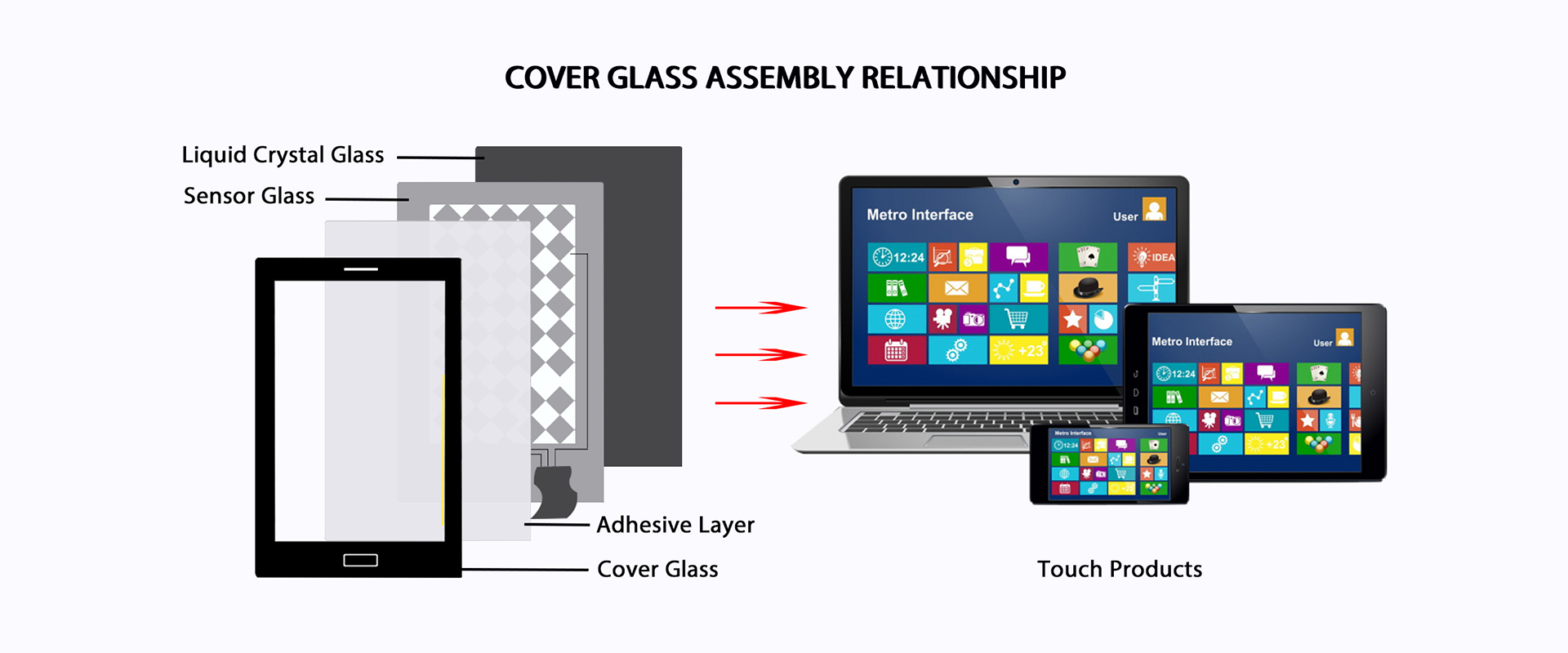

Mount on Touch Screen Display, Supports 0LED, LCD Display |

Application |

Mount on Touch Screen, Supports 0LED, LCD Display |

-

Step 1 Proofing CommunicationMake screen fixtures according to drawings or samples

Step 1 Proofing CommunicationMake screen fixtures according to drawings or samples -

Step 2 Confirm SamplesSend to customers for confirmation and adjustment of process details

Step 2 Confirm SamplesSend to customers for confirmation and adjustment of process details -

Step 3 Prepare Materials for ProductionProcess and produce according to the signed board and PO quantity

Step 3 Prepare Materials for ProductionProcess and produce according to the signed board and PO quantity -

Step 4 Finished Product InspectionProduction inspection, finished product inspection and level-by-level inspection

Step 4 Finished Product InspectionProduction inspection, finished product inspection and level-by-level inspection -

Step 5 Packaging and ShipmentDelivery on time, delivered to the customer's designated place

Step 5 Packaging and ShipmentDelivery on time, delivered to the customer's designated place -

Step 6 After-sales Worry-freeFull-time order follow-up, 24-hour after-sales follow-up

Step 6 After-sales Worry-freeFull-time order follow-up, 24-hour after-sales follow-up

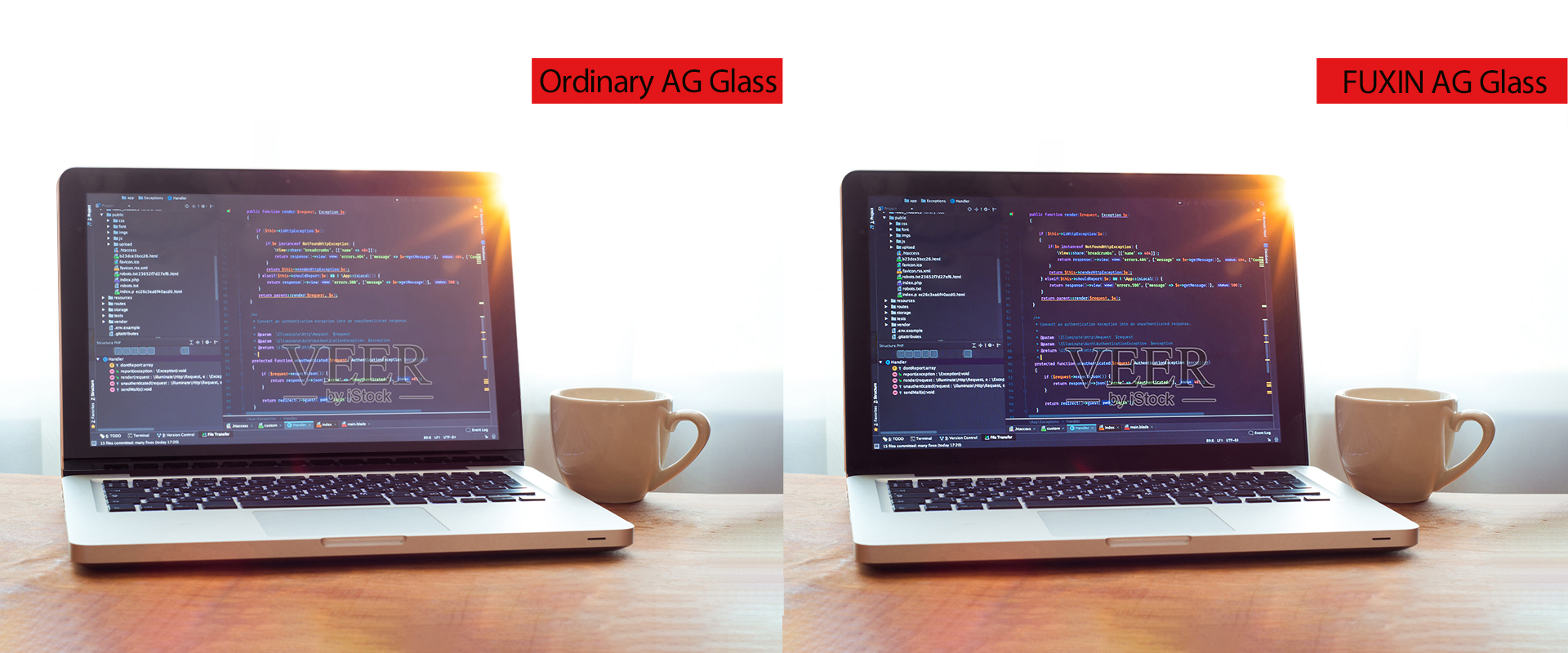

Anti-glare

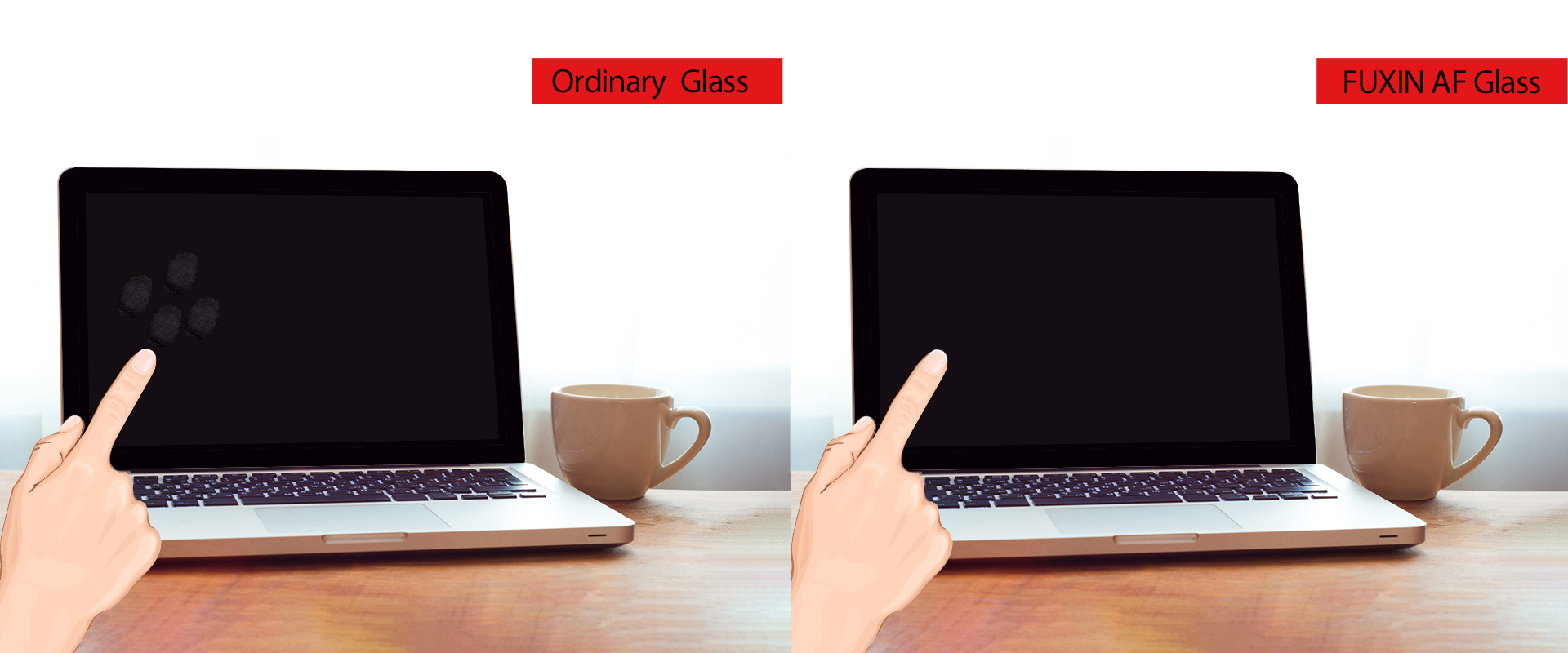

Anti-fingerprint

Hydrophobicity andoleophobicity

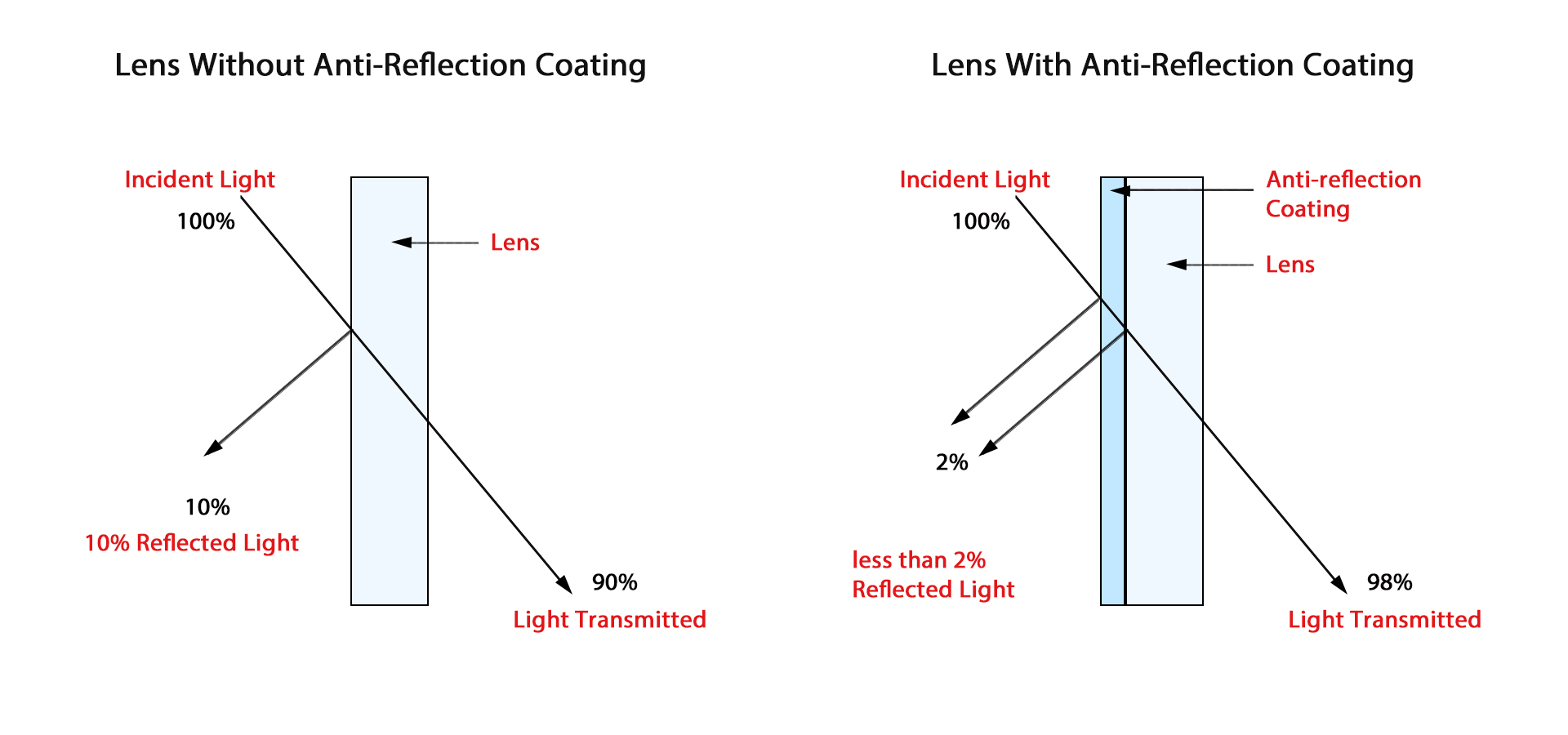

High Transmittance