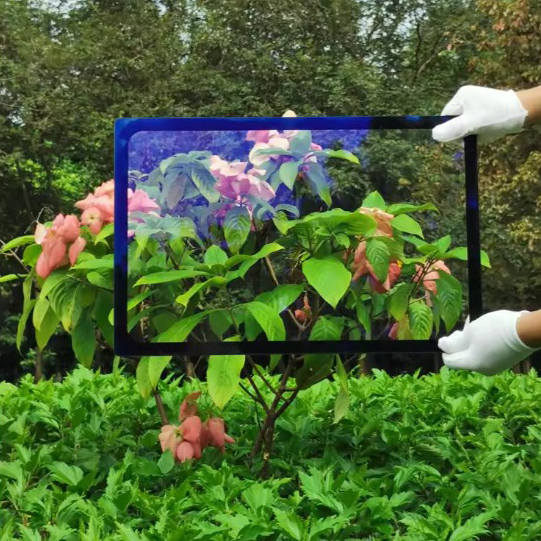

Customized interactive display AM cover glass

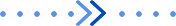

Product principle

Positively charged silver ions adsorb onto bacteria with attached charges, thereby disrupting the bacterial charge balance. Silver ions can easily penetrate into the interior of bacteria, affecting their respiration and reproduction. They can inhibit microbial growth, adsorb bacterial proteases, and quickly bind with them to destroy them, causing bacteria to lose their activity.

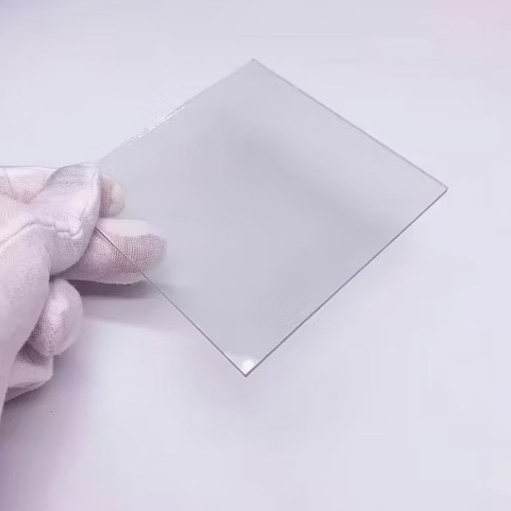

Functional film layer: silver dielectric

Surface: colorless and odorless

Post processing of antibacterial glass

1. This antibacterial glass can be chemically or physically tempered, and its tempering performance is the same as the standard value of non antibacterial glass.

2.Through subsequent processing of AF, dual functions of antibacterial and anti fingerprint can be achieved on the glass surface. The contact angle of water droplets is 110 °, which does not affect the original antibacterial efficiency.

3. Can be combined with AR anti reflective glass to achieve anti reflective optical effects.

Characteristics of antibacterial glass

Double sided antibacterial effect.

It can achieve a composite effect of antibacterial, anti fingerprint, and anti reflection.

Hot processing does not affect antibacterial efficiency (tempered steel, high-temperature silk screen printing, sandwich).

High broad-spectrum antibacterial activity (effective against various microorganisms).

High temperature resistance, can be used in combination with high borosilicate glass, fire-resistant and heat-resistant, etc.

The antibacterial surface has strong wear resistance, long-lasting antibacterial performance, and no decay in antibacterial performance.

It has infrared radiation properties and has good health benefits for the human body.

Safety, antibacterial agents are usually rigorously tested and harmless to humans and the environment.

Implementation method of antibacterial glass

Surface coating

Apply a coating containing antibacterial agents on the surface of glass.

Ion exchange

Antibacterial ions (such as silver ions) are embedded into the surface of glass through ion exchange technology.

Nanotechnology

Utilizing nanomaterials to evenly distribute antibacterial agents in glass.

Application fields of antibacterial glass

1. Medical field: Used for glass partitions, doors and windows in operating rooms, wards, laboratories, pharmaceutical preparation rooms and other places to reduce the risk of cross infection.

2. Food processing: Used for observation windows, display cabinets, etc. of food processing equipment to ensure food hygiene.

3. Public places: Glass facilities used in schools, shopping malls, public transportation, and other places to improve public health levels.

4. Household appliances: Glass panels used for refrigerators, microwaves, and other household appliances to prevent bacterial growth.

-

Step 1 Proofing CommunicationMake screen fixtures according to drawings or samples

Step 1 Proofing CommunicationMake screen fixtures according to drawings or samples -

Step 2 Confirm SamplesSend to customers for confirmation and adjustment of process details

Step 2 Confirm SamplesSend to customers for confirmation and adjustment of process details -

Step 3 Prepare Materials for ProductionProcess and produce according to the signed board and PO quantity

Step 3 Prepare Materials for ProductionProcess and produce according to the signed board and PO quantity -

Step 4 Finished Product InspectionProduction inspection, finished product inspection and level-by-level inspection

Step 4 Finished Product InspectionProduction inspection, finished product inspection and level-by-level inspection -

Step 5 Packaging and ShipmentDelivery on time, delivered to the customer's designated place

Step 5 Packaging and ShipmentDelivery on time, delivered to the customer's designated place -

Step 6 After-sales Worry-freeFull-time order follow-up, 24-hour after-sales follow-up

Step 6 After-sales Worry-freeFull-time order follow-up, 24-hour after-sales follow-up