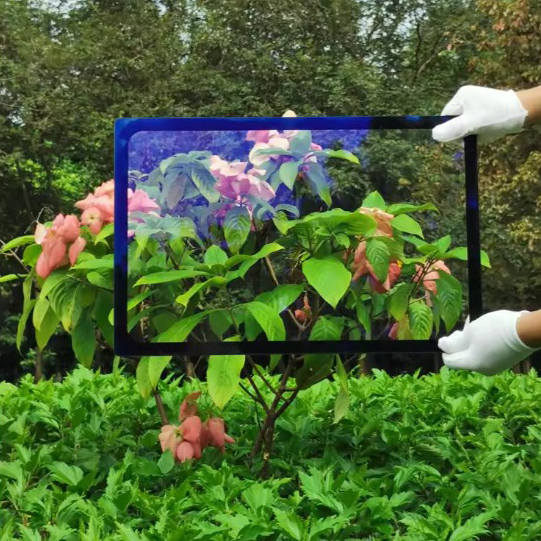

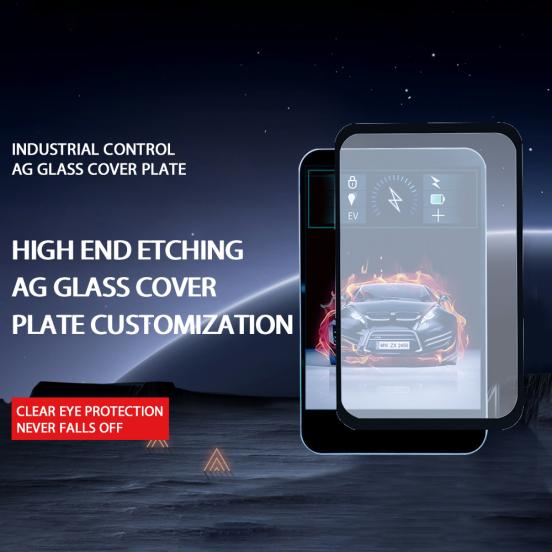

Customized AF Industrial Control Touch Screen Glass AG Tempered Glass Panel AR Coating Panel

Founded in 2012, FuXin Glass is a relatively large manufacturer of electronic and electrical glass in China. For more than ten years, the company has been deeply engaged in the research and development and manufacturing of professional glass for display (AG glass/AR glass/AF glass), electronic and electrical appliances (charging post glass/hood glass/elevator glass/toilet cover glass, etc.), lighting and industrial control and medical treatment, etc. The company has a strong quality management system and a fast-responding sales team to customize customized glass for you to be more competitive in the market.

|

Product Name |

FUXIN AG Glass |

|

Types of Glass |

soda-lime , borosilicate, aluminosilicate etc |

|

Min & Max Dimension |

3.3~55 inches |

|

Thickness |

0.55mm,0.7mm,1.1mm,1.8mm,2.0mm,3.0mm,4.0mm 6mm,etc |

|

Shape |

round, square, or customized |

|

Edge |

Flat ground ,polished, smooth pencil edge etc. |

|

Surface Treatments |

AG, AR, AF, AM,ITO, Mirror... |

|

Printing |

silk screen printing, ceramic printing, digital printing for customizing graphic edge |

|

Impact Resistance |

≥IK07 (Thermal tempering & chemical strengthening) |

|

Stress value |

>450Mpa |

|

Stress layer |

>8um |

|

Surface Mohs hardness |

5.5H |

|

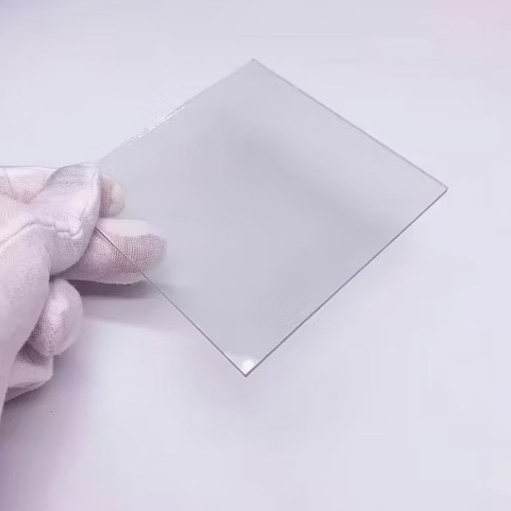

Transmittance |

>89% |

|

Glossiness |

70±10 |

|

Roughness |

0.12±0.05mm |

|

Haze |

4.7% |

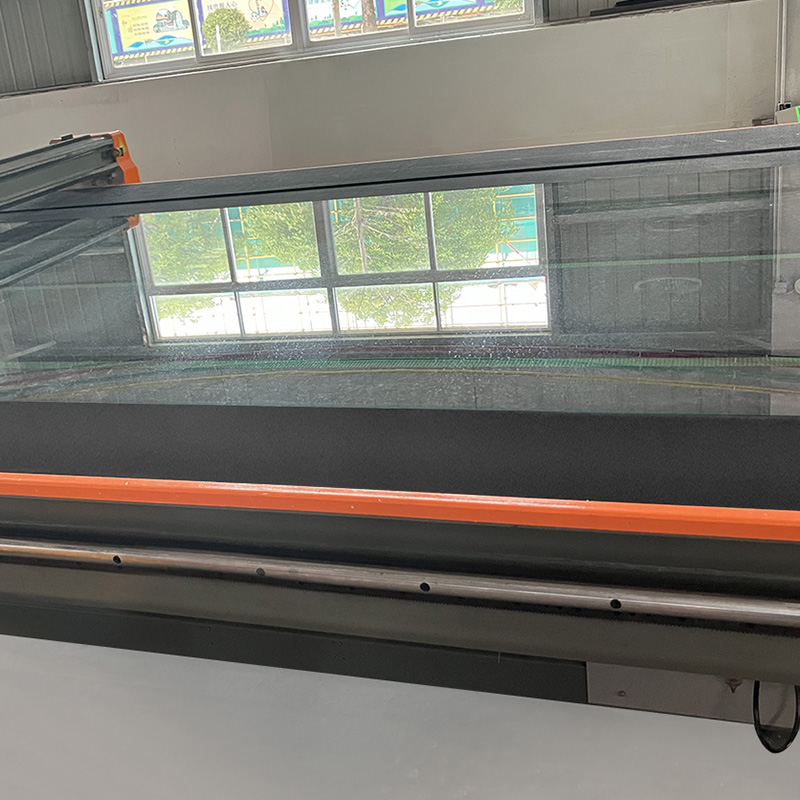

Processing technology of industrial control glass cover plate

about projectIndustrial control cover glass production process: glass cutting - CNC grinding (chamfering, drilling) - tempering (physical tempering, chemical tempering) - silk screen printing pattern (color can be customized) - surface treatment (AG,AR,AF,AM) - cleaning - packaging.

These processes ensure the high light transmission and strong scratch resistance of the glass cover, which is an important component of display products.

Specific process description

Slicing

Cutting the raw material to the required size.

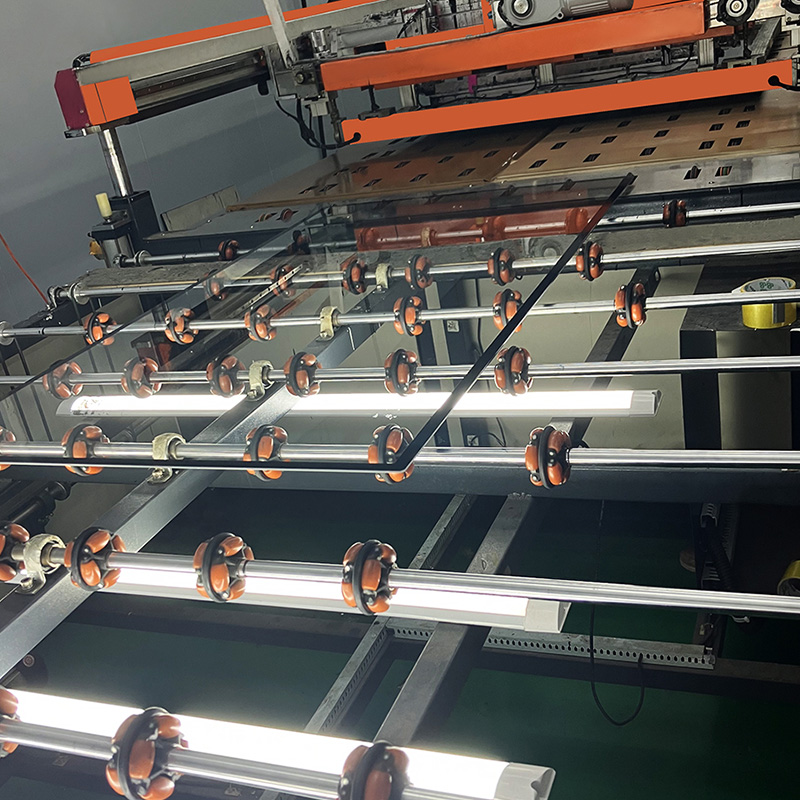

Edge Grinding

Grind the cut glass to make sure the edge is smooth.

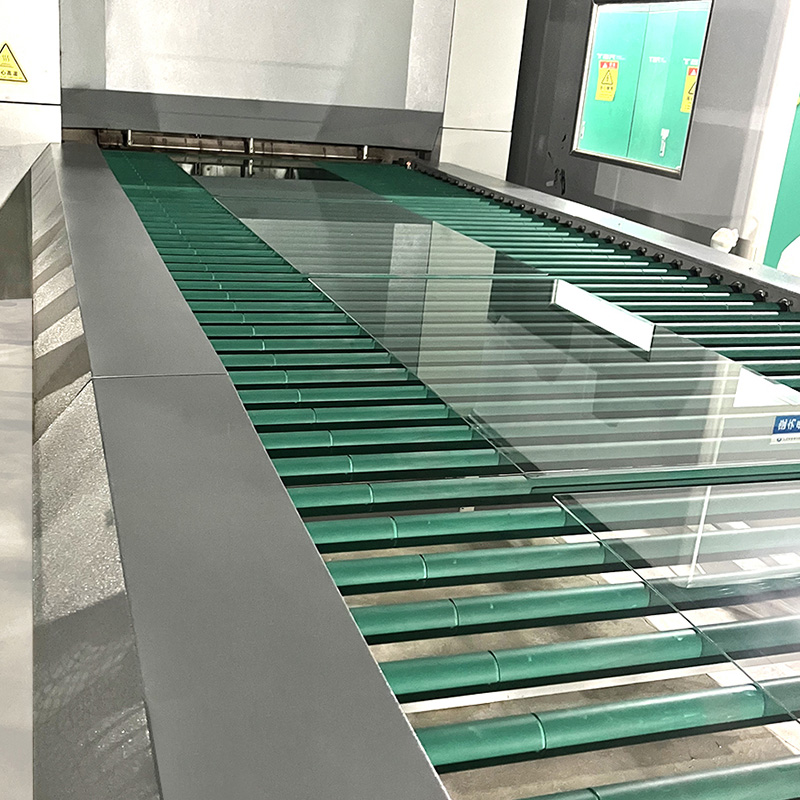

Tempering

Enhancing the hardness and impact resistance of glass by physical or chemical means.

Screen Printing

Printing different colors, patterns, and markers on the glass surface.

Surface treatment

Forms a protective layer on the glass surface to improve light transmittance and properties such as reflection reduction or fingerprint resistance.

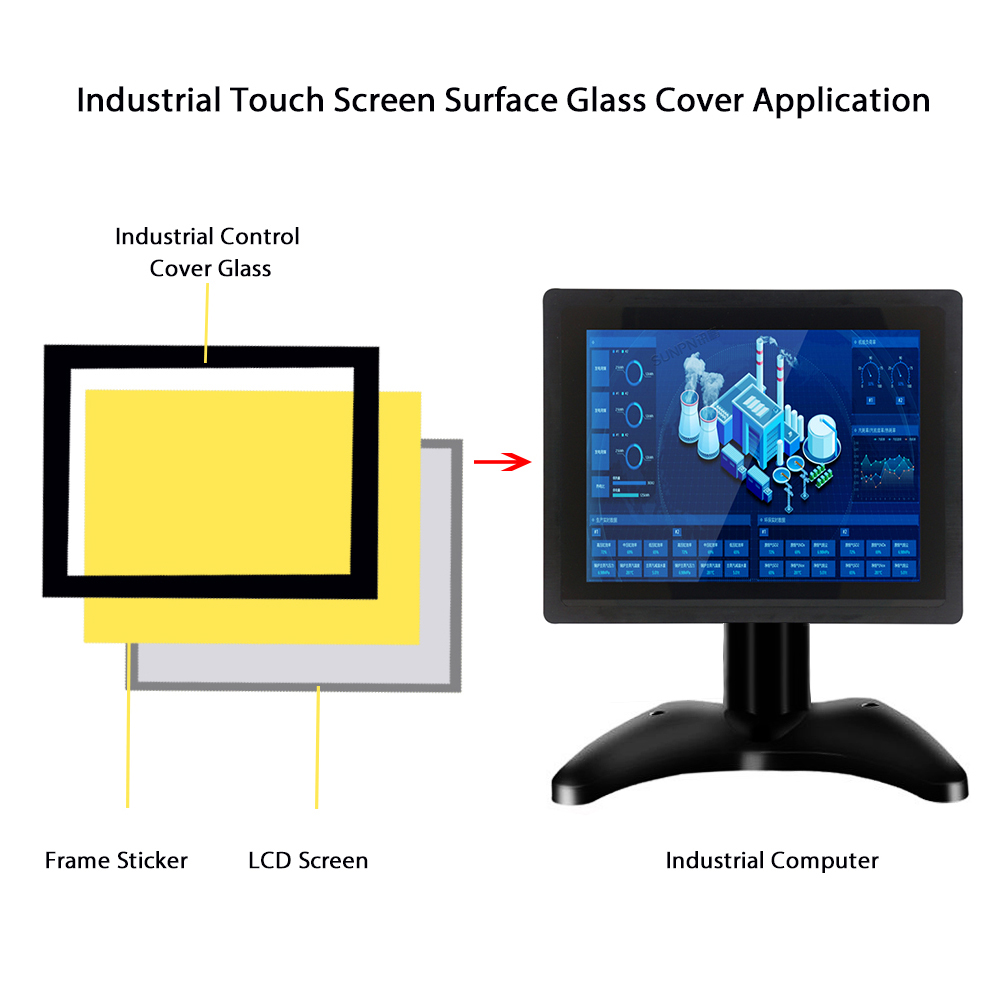

Market Demand and Application Areas of Industrial Control Glass Covers

about projectWith the popularization and development of touch technology, capacitive touch screen solutions have become the mainstream of human-computer interaction in mobile terminals such as cell phones, tablet PCs, touch notebooks and other mobile terminals by virtue of its stable performance, good tactile sensation and other advantages. No matter what kind of touch control technology, the cover is an essential protection component, and the glass cover has gradually become the mainstream of the cover due to its high light transmittance and strong anti-scratch properties.

Main application areas:

The development trend of industrial control glass cover plate

With the progress of science and technology and the growth of market demand, the development trend of industrial control glass cover plate is mainly reflected in the following aspects:

High-performance

The future industrial glass cover plate will pay more attention to high performance, such as higher light transmittance, stronger impact resistance and better anti-fingerprint performance.

Diversification

In order to meet the needs of different customers, the types of industrial glass cover plate will be more diversified, such as AR, AG, AF, glass cover plate and AM antibacterial glass cover plate.

Environmentalization

With the improvement of environmental protection consciousness, the production process of industrial glass cover plate will be more environmentally friendly, such as the use of non-polluting raw materials and production processes.

Intelligent

The future industrial glass cover plate will pay more attention to intelligence, such as integrated touch screen function, support voice recognition, etc..