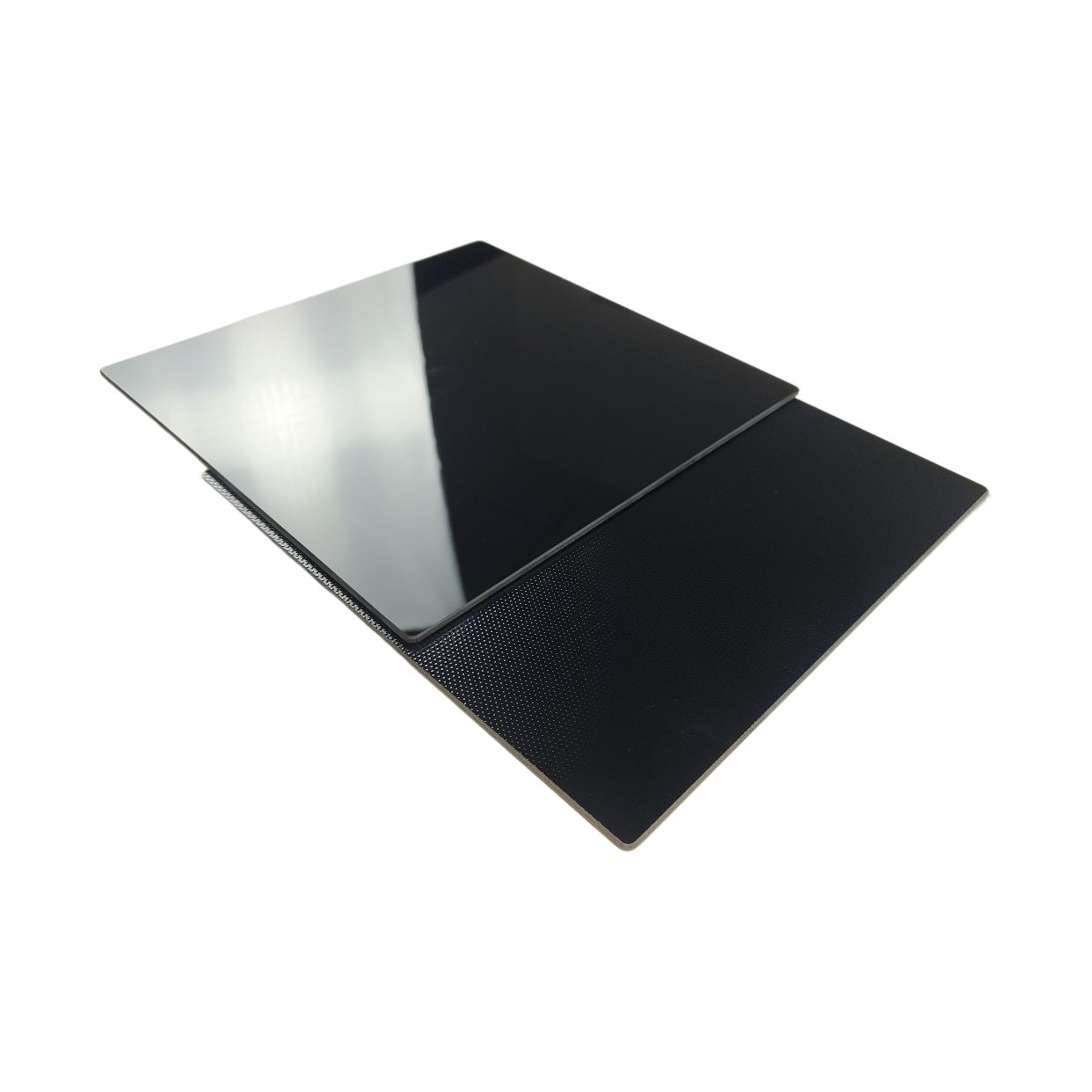

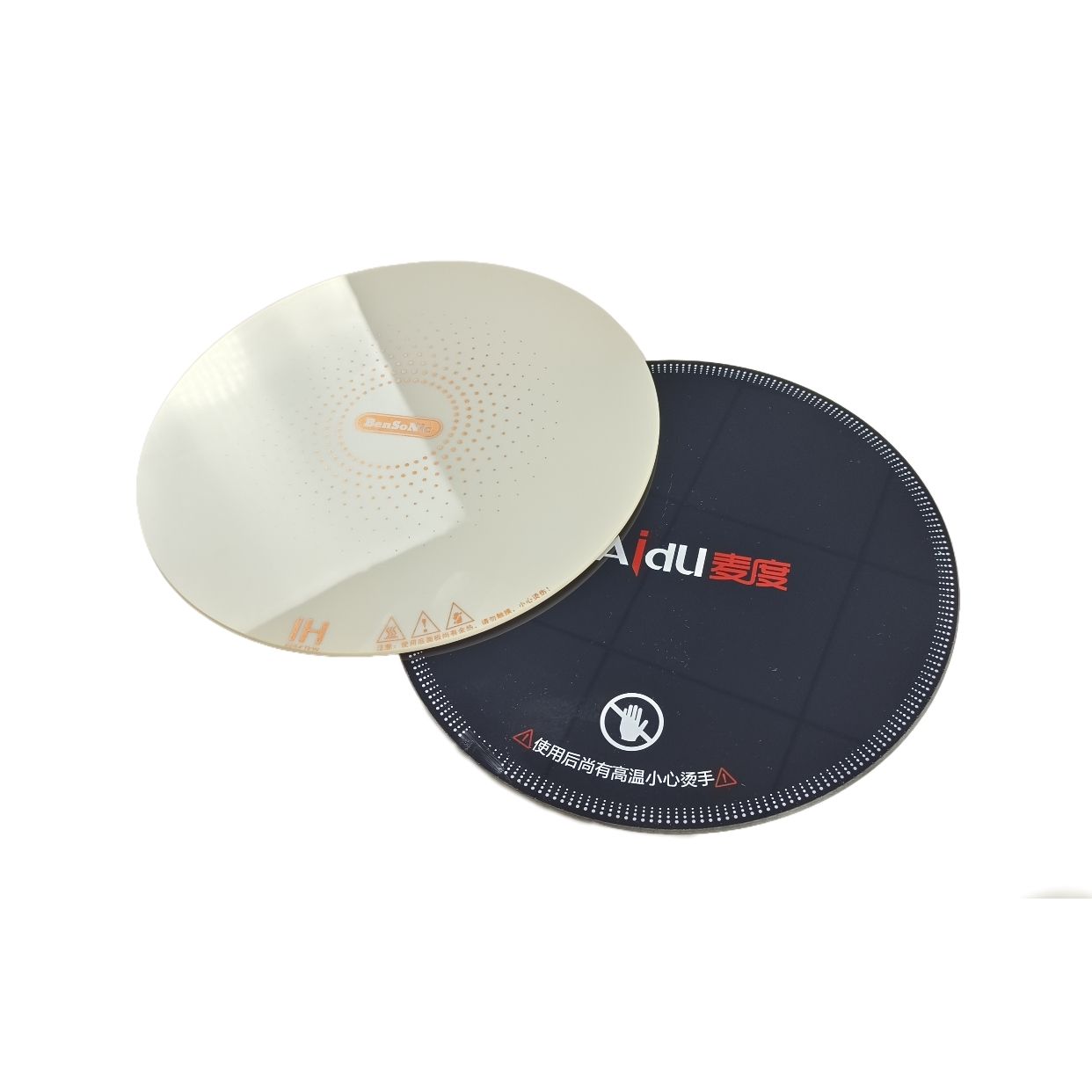

4mm Custom Black Ceramic Glass Panel for High Temperature Applications

Customizable Specifications

| Parameter | Specification |

| Thickness Specifications | Standard: 4mm (Custom thicknesses available: 3mm/5 mm/6 mm, etc.) |

| Material Type | Black ceramic glass |

| High-temperature resistance | Long-term operating temperature: ≤800°C; Short-term peak temperature: ≤1200°C |

| Thermal Stability | Temperature difference between sudden cooling and heating: ≤300°C |

| Surface hardness | Magnitude 6.5 |

| Coefficient of Thermal Expansion | ≤4.0×10⁻⁶/℃(20℃~500℃) |

| Light Blocking Rate | ≥98% |

| Insulation Properties | Breakdown voltage ≥ 15 kV/mm |

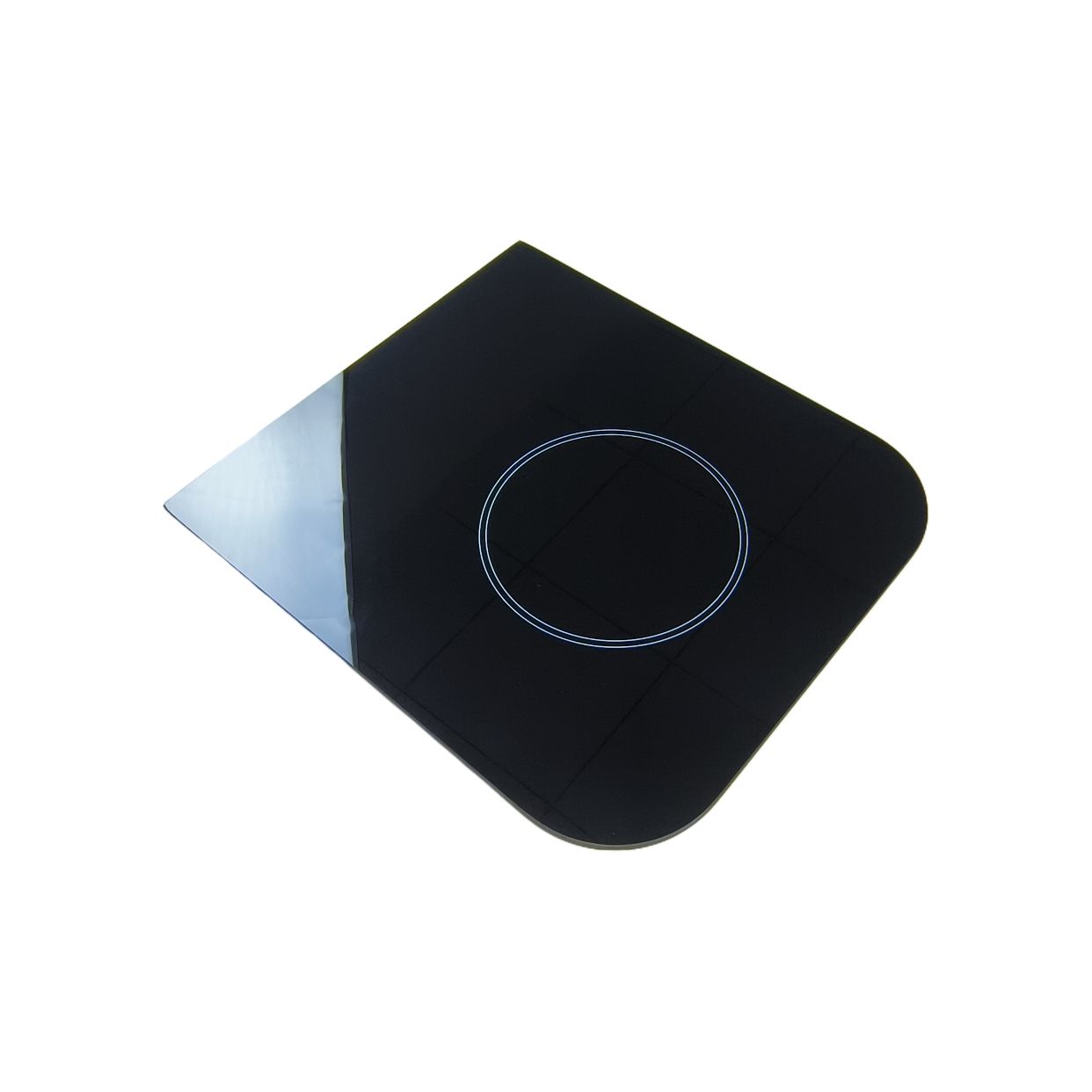

| Customization Scope | Fully customizable dimensions, cutouts, shapes, and printed patterns |

Core Features

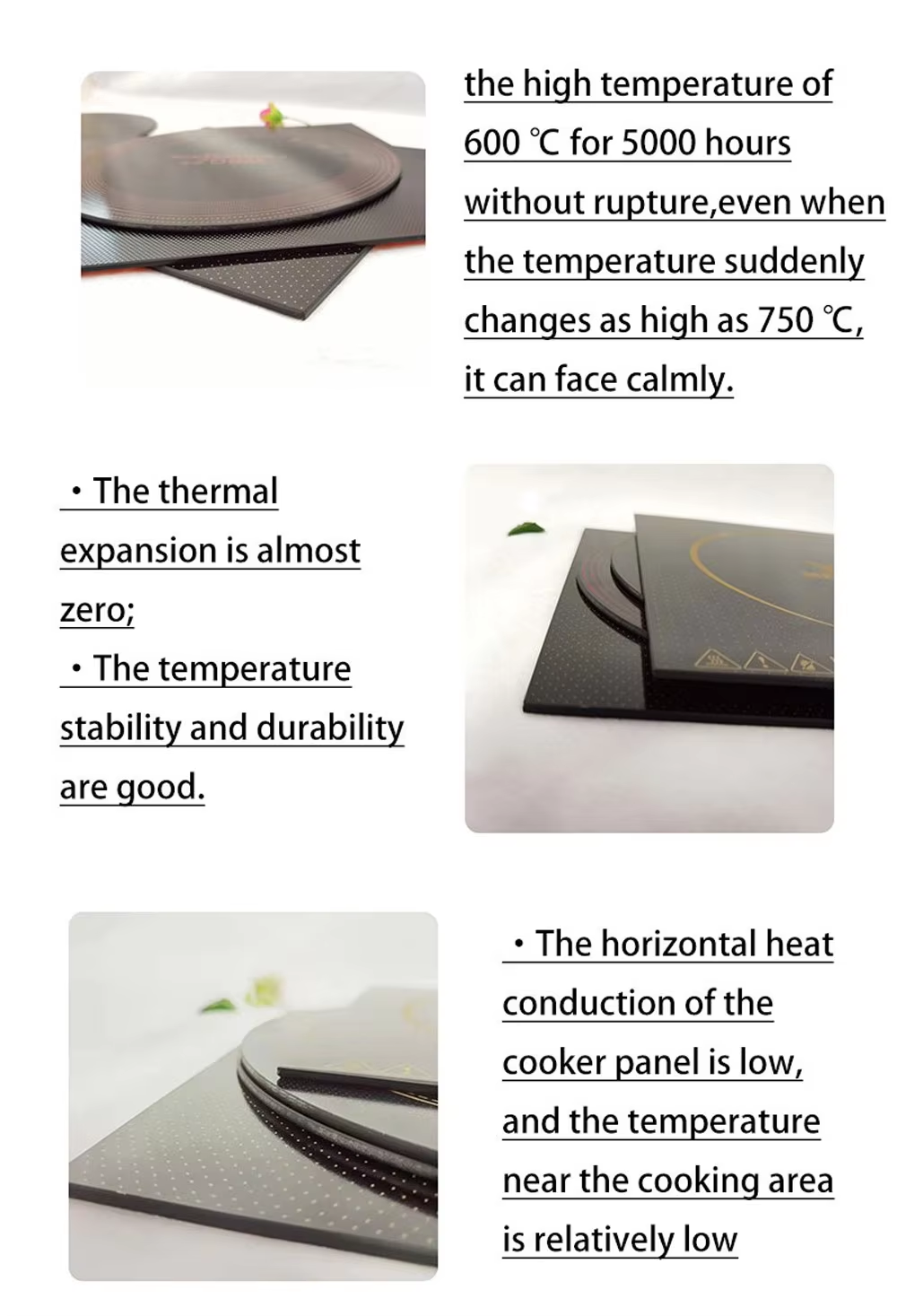

1. Ultimate High-Temperature Resistance

Constructed from specialized ceramic-glass composite materials, it withstands temperatures up to 1200°C (short-term) / 800°C (long-term). It can directly contact high-temperature heat sources without shattering or warping. With exceptional thermal stability, it tolerates rapid temperature changes of up to 300°C, completely eliminating the vulnerability of ordinary glass to high-temperature breakage. It is perfectly suited for extremely high-temperature working environments.

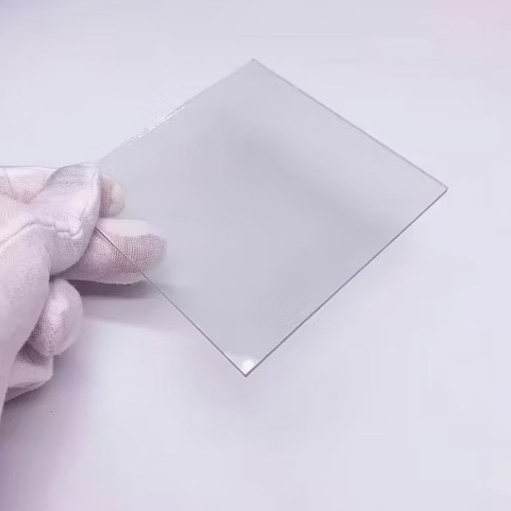

2. Industrial-grade rugged material

4mm thickness optimized design delivers three times the impact resistance of ordinary glass, with a surface hardness of 6.5 on the Mohs scale. Scratch-resistant and wear-resistant, it resists marring. The dense, non-porous material is moisture-proof and corrosion-resistant, withstanding industrial environments including acidic/alkaline gases and oil contamination. Its service life exceeds that of standard high-temperature glass by over five times.

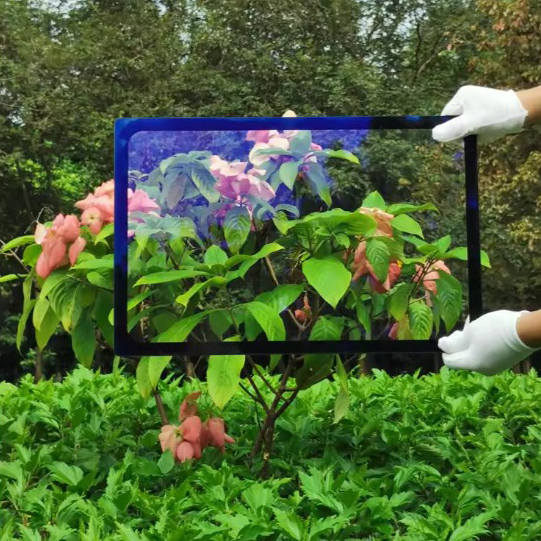

3. Fully Customizable Adaptation

Supports complete customization of dimensions, cutout positions, aperture sizes, edge chamfers, and cutting shapes to accommodate diverse equipment installation requirements. The black ceramic material offers superior light blocking with a light blockage rate ≥98%. It can be paired with screen printing processes to customize functional markings and scale lines (precision ±0.1mm), meeting equipment visualization needs.

4. Stable and reliable physical properties

Low thermal expansion coefficient (≤4.0×10⁻⁶/℃), excellent dimensional stability in high-temperature environments with no significant thermal deformation. Superior insulation performance, breakdown voltage ≥15kV/mm, suitable as an insulating protective panel for high-temperature equipment to ensure operational safety.

Company Introduction

Founded in 2012, Fuxin Glass is a leading manufacturer specializing in the research, development, production, and export of cover glass, headquartered in Dongguan, China, near the ports of Shenzhen and Guangzhou.

With 13 years of industry experience, Fuxin serves customers in over 80 countries worldwide. With ISO/RoHS/JIS Z certifications, Fuxin Glass is dedicated to providing high-quality glass solutions for electronic displays and smart devices. Its products are widely used in interactive display, automotive electronics, industrial equipment, medical devices, home appliances, and smart devices. The products feature high light transmittance (over 95%), high hardness (Mohs 6), and excellent scratch and impact resistance. The 21,000-square-meter factory is equipped with four fully automated production lines, with a monthly production capacity of 300,000 pcs. We support small-batch trial production and large-scale delivery, and provide one-step technical support and after-sales service. Multi-dimensional customization is supported as well: including but not limited to mold design (samples can be produced in as fast as 7 days), special optical processing (AR/AF/AG/AM combination), explosion-proof structure design (multi-layer composite structure), color customization (7 colors are optional), silk screen logo, etc., to meet the personalized needs of customers. Our products have successfully entered mainstream markets such as North America, Japan, South Korea, India, and Europe, and widely serve interactive ( such us all in one machine, IFPD, smart white board ), automotive central control screens, industrial HMI, smart home panels and other fields.

We always adhere to the principle of "integrity, quality and win-win" and are willing to establish good long-term cooperative relationships with customers all over the world!

Inspection Progress

Factory Overview

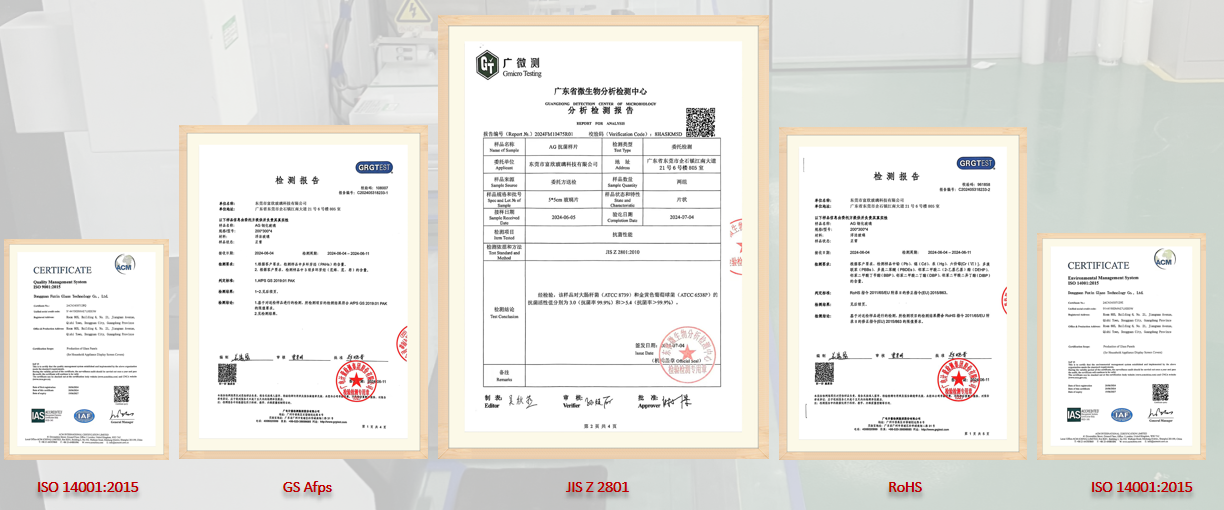

Certification

Package

Delivery & Lead Time

| Original Country | China |

| FOB Port | Shenzhen or Hongkong |

| HS Code | 700719000 |

| Lead Time | Sample within 7 days, bulk order 15~20 days |

| Delivery | By sea / DHL / Fedex / UPS |

Payment Details

-

1

1) Are you a trading company or manufacturer?

1. Leading glass deep processing factory

2. 13 years of experience

3. OEM/ODM expertise -

2

2) How to order?

1. Your detailed requirements: drawings/quantity/or your special requirements.

2. Let's get to know each other better: We can provide your requirements.

3. Email us your formal order, payment.

4. We will incorporate the order into our mass production plan and produce according to the approved sample.

5. Packing & shipping -

3

3) Do you provide samples for testing?

We can provide free samples, but the shipping cost will be borne by the customer.

-

4

4) What is your minimum order quantity?

A: 200 pieces.

-

5

5) How long does a sample order take? How about a bulk order?

Sample order: Usually within a week.

Bulk order: Usually takes 15~20 days depending on quantity and design. -

6

6) What packaging do the products use?

Plastic wrap + pearl cotton + kraft paper + cartoon box + wooden crate.

-

7

7) How do you ship the goods, and how long does it take to arrive?

We usually ship by sea / air freight/ International Express, and the arrival time depends on the distance.

-

8

8) What are your payment terms?

A: T/T 100% in advance, or other payment methods.

-

9

9) Do you provide OEM/ODM services?

Yes, we can customize.

-

9

10) Do your products have certificates?

Yes, we have ISO9001/REACH/RoSH/GS/JIS Z certifications.