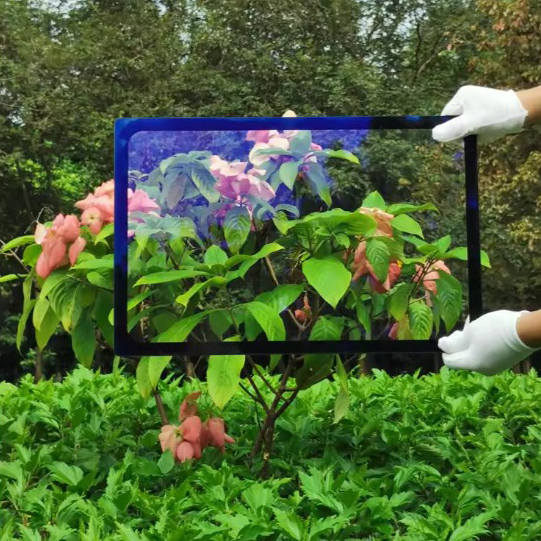

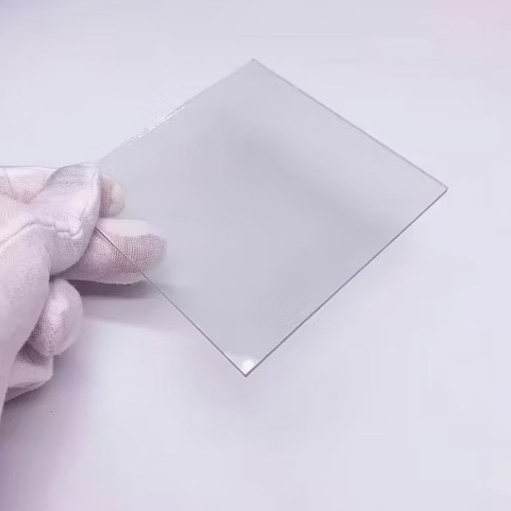

Custom 5.56mm round edge panel glass for weighing scale

|

Product Name |

Silk screen printed glass |

Scope of application |

Home Appliance, Electronics & Instruments |

|

Product Material |

Nanbo, Taibo, White Glass, Ultra White Glass, Soda Lime, Low Iron Glass |

Processing technology |

Water grinding, fine carving, polished edges, tempered, silk screen printing |

|

Surface Treatment |

Ar/Af/AG or Customized |

Size |

Customized as Request |

|

Color |

Customized as Request |

Thickness |

From 0.23mm to 12mm |

|

Product Tolerance |

±0.1 |

Quality |

Quality is not up to standard, returns are accepted |

|

Technics |

Thermal Tempering/Chemical Tempering |

Craftsmanship Effect |

The product is safer, more aesthetically pleasing, and of higher quality |

|

Edgework |

Flat Ground (Flat/Pencil/Bevelled/Chamfer Edge are available) |

Hole |

Round/Square (Irregular hole are available) |

|

Printing Method |

Normal Silkscreen/High Temperature Silkscreen |

Features |

Anti-scratches/Waterproof/anti-fingerprint/anti-fire/easy to clean/high-pressure scratch resistant |

|

Sample printing |

Samples can be made based on provided samples or drawings |

Price |

Depending on style and quantity |

|

Production Cycle |

8 days |

Transport Package |

Wooden Case Package |

Household Appliance Tempered Glass

Definition: Safety tempered glass used in home appliances, serving as protection for panels,doors, or displays, balancing strength and aesthetics.

Process: Physical tempering: Glass is heated to about 700°C, then rapidly cooled with air tocreate surface compressive stress (3-22mm thickness is fully tempered, <3mm is semi-tempered/chemical tempered).

Deep processing: Edge grinding/beveling (smooth edges to prevent scratching), drilling (for appliance button holes), silk-screen printing (for labels/decorations), coating (AR high transparency, AG anti-glare to optimize display).

Features.

Safety protection: lmpact-resistant (can withstand a 1.5kg steel ball dropping from 1m height), shatters into non-sharp fragments.

Aesthetic and durable: Transparent texture enhances appliance quality, scratch-resistant (canbe cleaned directly with a steel wool ball, no surface scratches), oil stain-resistant (easy to clean).

Function compatibility: Oven glass: High temperature resistant (less than 300°C), clear observation of intemal cooking.

Refrigerator glass: Fog-resistant treatment (does not fog in low-temperature environments). showcases ingredients.

Applications: Kitchen appliances: Oven door glass, induction cooker touch panels, microwavedoors.

Living appliances: Washing machine control glass, refrigerator display glass (with silk-screendecoration strips/brand logo), air purifier displays.

Small appliances: Operation panels of coffee machines and juicers (with silk-screen scales/icons).

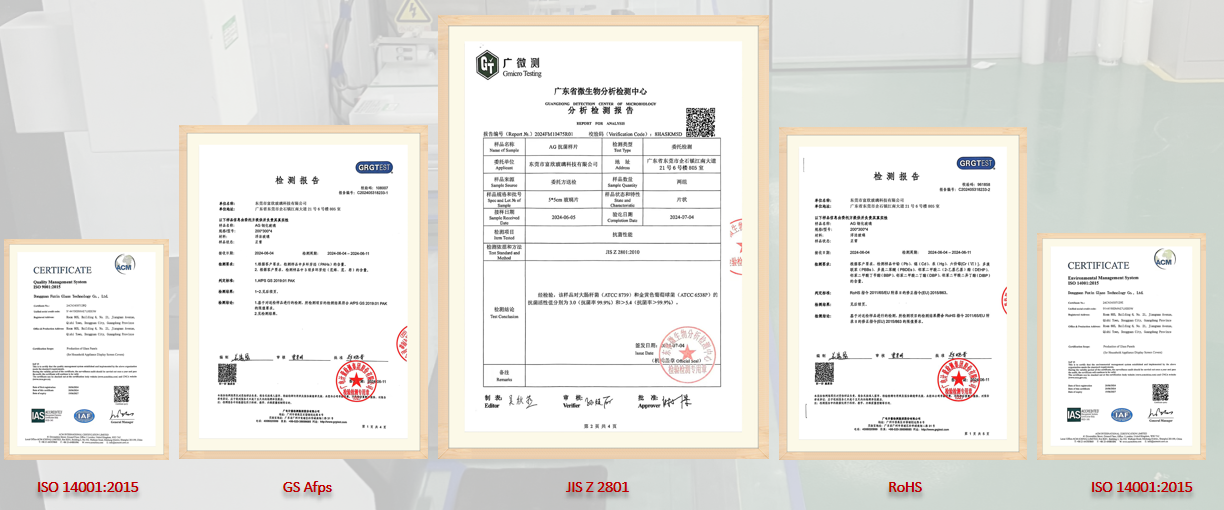

COMPANY INTRODUCTION

Founded in 2012, registered capital $150 million, Fuxin Glass is an ODM/OEM supplier of touch screen cover glass, lighting glass, and electronic and electrical glass with over 13 years of experience. The factory boasts a comprehensive suite of precision glass processing equipment, including glass tempering lines, fully automatic CNC cutting and edging lines, a large-scale screen printing line, linear and custom-shaped edging machines, and AG, AF, AR, and Anti-bacterial glass spraying. Fuxin Glass is certified to ISO 9001:2015 and ISO 14001:2015 quality management systems, JIS Z 2801:2010 AM glass testing, and ROHS compliance. Leveraging a strong R&D and sales team, production capacity, and a stable supply chain, Fuxin Glass has grown to become one of China's top three electronic and electrical glass manufacturers and enjoys a global reputation. We maintain stable partnerships with many renowned global brands, including TCL, HKC, HUAWEI, KONKA, and Hisense. The company has a team of over 50 leading professional technical personnel. Based on the enterprising thinking of building a business with integrity, creating a new future, technological creativity and leading by science and technology, we are constantly innovating. We always adhere to the principle of "integrity, quality and win-win" and are willing to establish good long-term cooperative relationships with customers all over the world!

SHIPPING AND PAYMENT

-

1

1) Are you a trading company or manufacturer?

1. Leading glass deep processing factory

2. 13 years of experience

3. OEM/ODM expertise -

2

2) How to order?

1. Your detailed requirements: drawings/quantity/or your special requirements.

2. Let's get to know each other better: We can provide your requirements.

3. Email us your formal order, payment.

4. We will incorporate the order into our mass production plan and produce according to the approved sample.

5. Packing & shipping -

3

3) Do you provide samples for testing?

We can provide free samples, but the shipping cost will be borne by the customer.

-

4

4) What is your minimum order quantity?

A: 200 pieces.

-

5

5) How long does a sample order take? How about a bulk order?

Sample order: Usually within a week.

Bulk order: Usually takes 15~20 days depending on quantity and design. -

6

6) What packaging do the products use?

Plastic wrap + pearl cotton + kraft paper + cartoon box + wooden crate.

-

7

7) How do you ship the goods, and how long does it take to arrive?

We usually ship by sea / air freight/ International Express, and the arrival time depends on the distance.

-

8

8) What are your payment terms?

A: T/T 100% in advance, or other payment methods.

-

9

9) Do you provide OEM/ODM services?

Yes, we can customize.

-

9

10) Do your products have certificates?

Yes, we have ISO9001/REACH/RoSH/GS/JIS Z certifications.