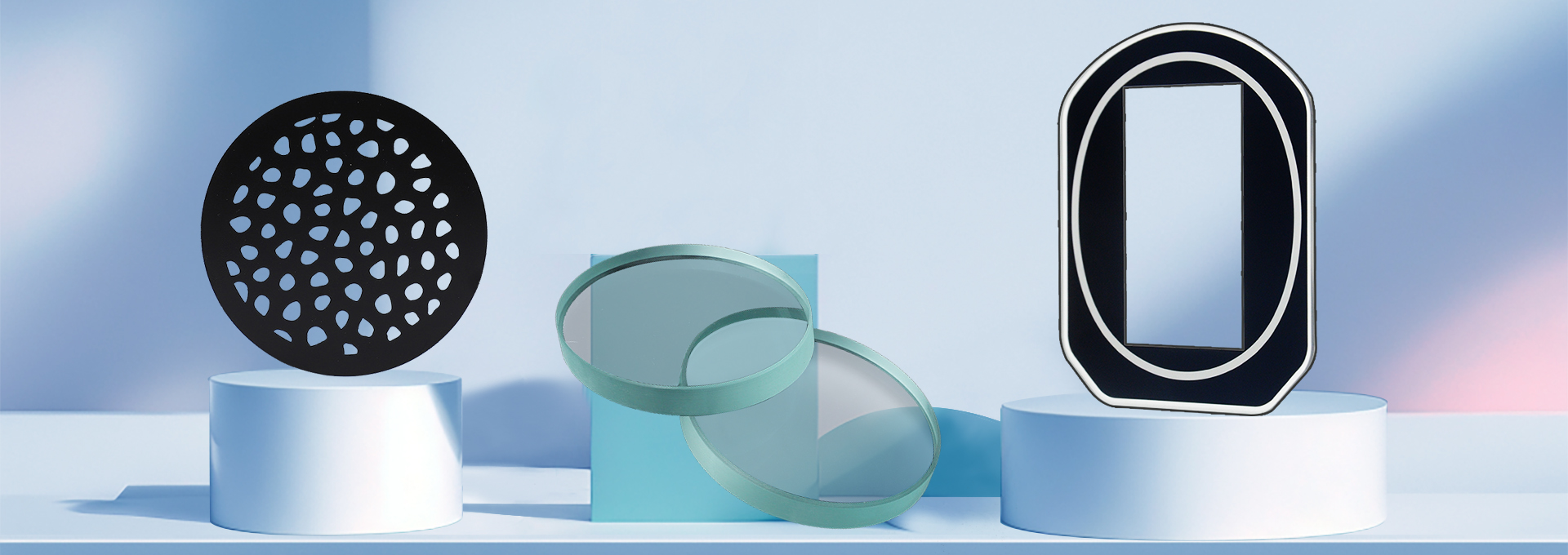

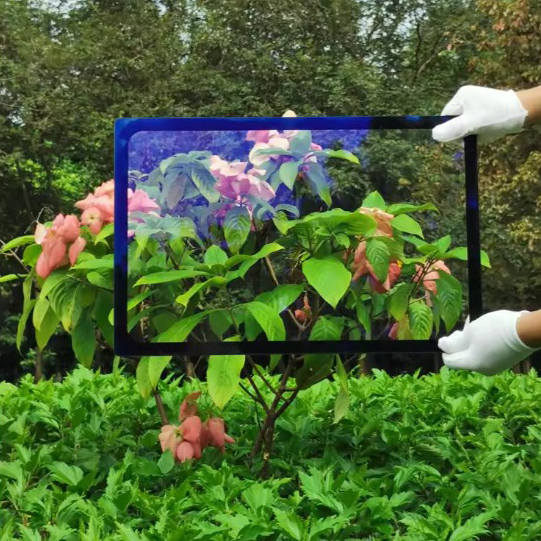

3.2mm/4mm Tempered Solar Glass Ultra-Transparent Low Iron Patterned for Solar Collectors Solar Panels

Customizable Specifications

| Thickness tolerance | 3.2±0.2mm |

| Dimensions | 300mm*300mm~1050mm*2000mm |

| Solar Transmittance | ≥ 91.7﹪ (Raw glass) |

| Poisson’s Ratio | 0.2 |

| Density | 2.5g/cc |

| Young's Modulus | 73GPa |

| Tensile Strength | 42MPa |

| Hemispherical emissivity | 0.84 |

| Thermal Expansion Coefficient | 9.03×10-6/℃ |

| Softening Point | 720ºC |

| Annealing Point | 550ºC |

| Strain Point | 500ºC |

| Usage | Industrial, Solar, Greenhouse, Lighting, Instrument |

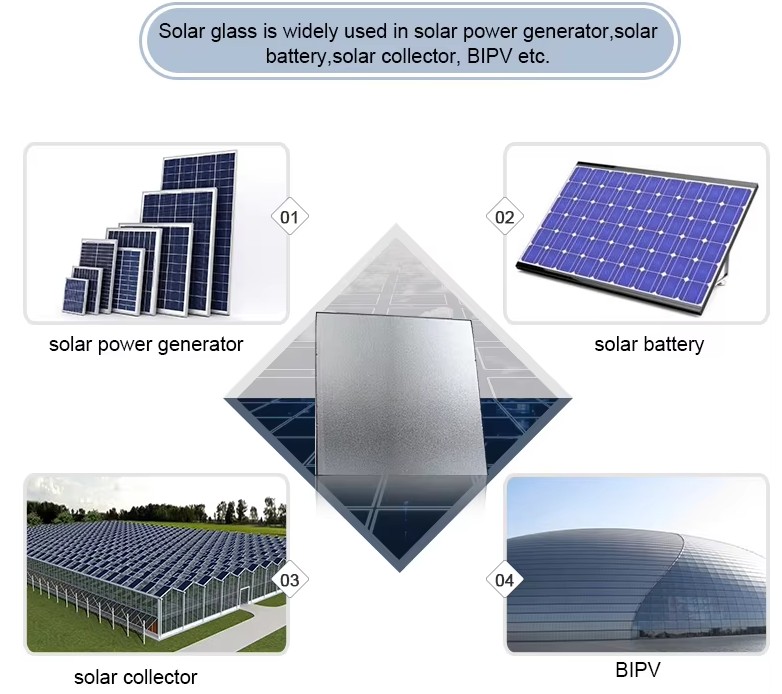

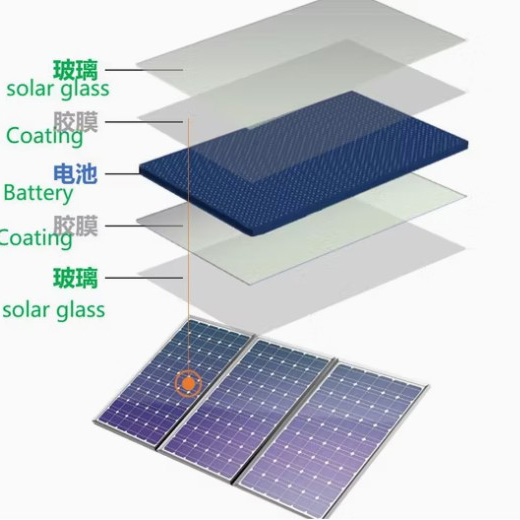

Product Application

Company Introduction

Founded in 2012, Fuxin Glass is a leading manufacturer specializing in the research, development, production, and export of cover glass, headquartered in Dongguan, China, near the ports of Shenzhen and Guangzhou.

With 13 years of industry experience, Fuxin serves customers in over 80 countries worldwide. With ISO/RoHS/JIS Z certifications, Fuxin Glass is dedicated to providing high-quality glass solutions for electronic displays and smart devices. Its products are widely used in interactive display, automotive electronics, industrial equipment, medical devices, home appliances, and smart devices. The products feature high light transmittance (over 95%), high hardness (Mohs 6), and excellent scratch and impact resistance. The 21,000-square-meter factory is equipped with four fully automated production lines, with a monthly production capacity of 300,000 pcs. We support small-batch trial production and large-scale delivery, and provide one-step technical support and after-sales service. Multi-dimensional customization is supported as well: including but not limited to mold design (samples can be produced in as fast as 7 days), special optical processing (AR/AF/AG/AM combination), explosion-proof structure design (multi-layer composite structure), color customization (7 colors are optional), silk screen logo, etc., to meet the personalized needs of customers. Our products have successfully entered mainstream markets such as North America, Japan, South Korea, India, and Europe, and widely serve interactive ( such us all in one machine, IFPD, smart white board ), automotive central control screens, industrial HMI, smart home panels and other fields.

We always adhere to the principle of "integrity, quality and win-win" and are willing to establish good long-term cooperative relationships with customers all over the world!

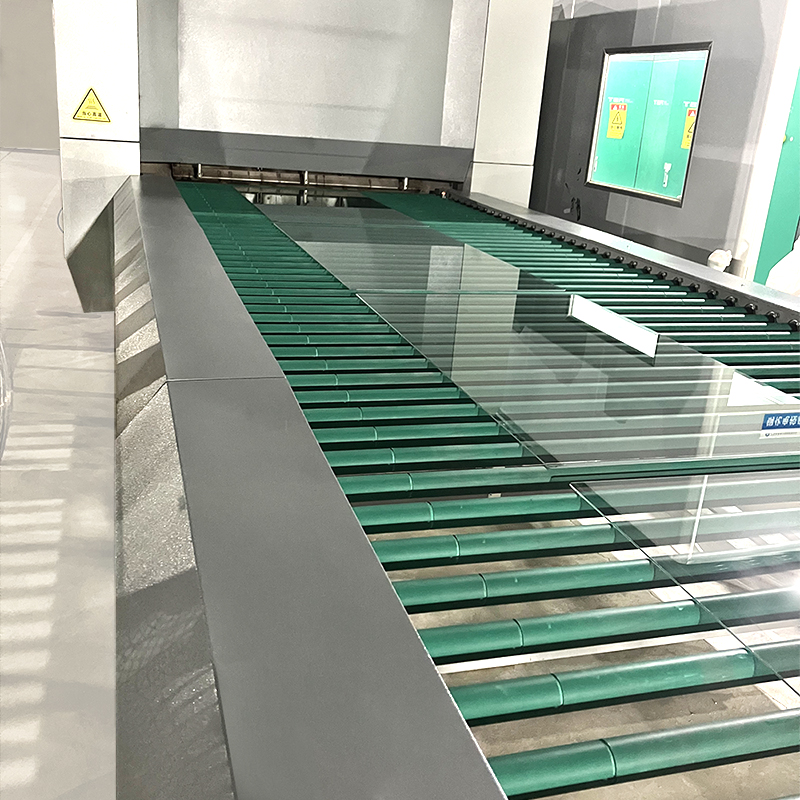

Inspection Progress

Factory Overview

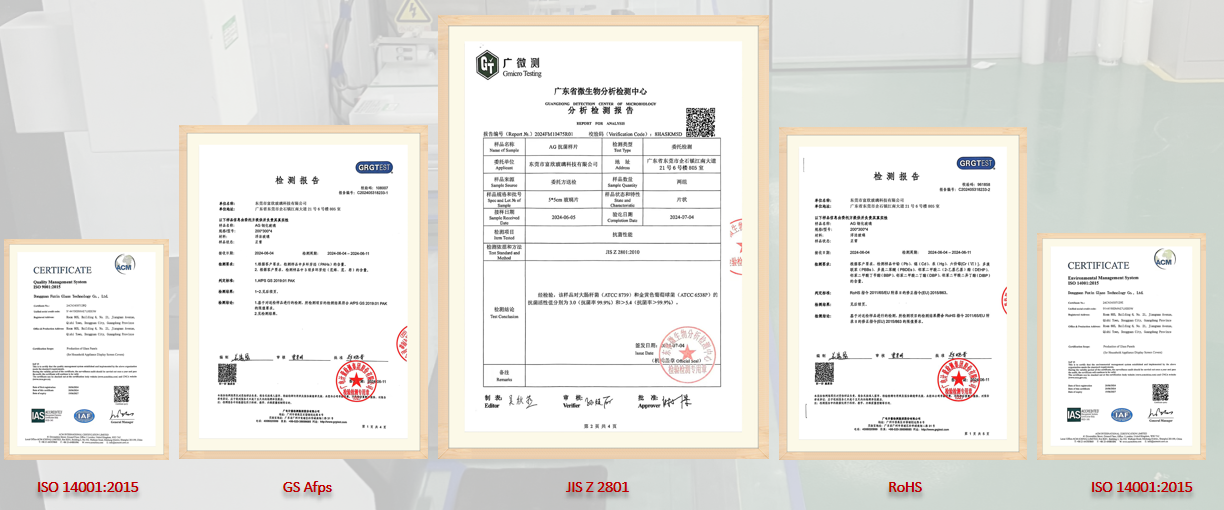

Certification

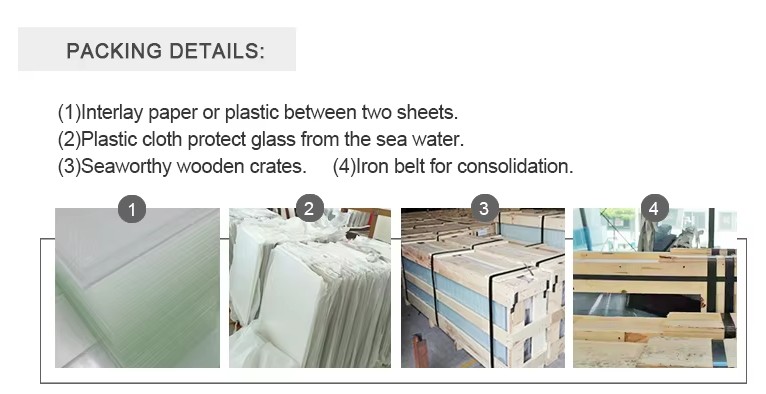

Package

Delivery & Lead Time

| Original Country | China |

| FOB Port | Shenzhen or Hongkong |

| HS Code | 700719000 |

| Lead Time | Sample within 7 days, bulk order 15~20 days |

| Delivery | By sea / DHL / Fedex / UPS |

Payment Details

1. Glass Materials Used in Solar Glass

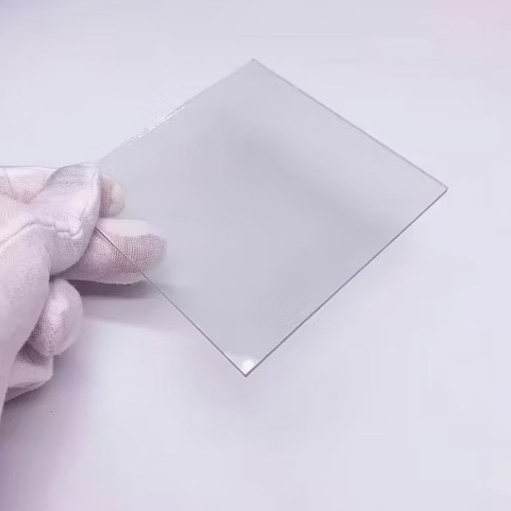

Low-Iron (Ultra-Clear) Glass

-

-

Role: This is the standard and most critical substrate for solar panels. It has a significantly reduced iron oxide content compared to regular float glass.

-

Function: Minimizes the greenish tint and maximizes light transmittance (typically >91% for 3.2mm thickness). Allowing more sunlight to reach the solar cells directly increases the module's power output and efficiency.

-

Tempered (Heat-Strengthened) Glass

-

-

Role: The low-iron glass is almost always tempered for use in solar modules.

-

Function: Provides exceptional mechanical strength to withstand hail impact, wind loads, and snow. It enhances thermal shock resistance. Upon breakage, it crumbles into small, less hazardous granules instead of sharp shards, improving safety.

-

2. Surface Treatments

Anti-Reflective (AR) Coating

-

-

Process: Typically applied via atmospheric pressure chemical vapor deposition (APCVD) or sol-gel methods during the glass manufacturing (online) or later (offline). It creates a porous, nano-textured layer.

-

Function: Reduces the reflection of sunlight from the glass surface (from ~4% to <1%) by creating an optical gradient. This increases the amount of light entering the module, especially during low-angle incidence (morning, evening, winter), leading to higher energy yield.

-

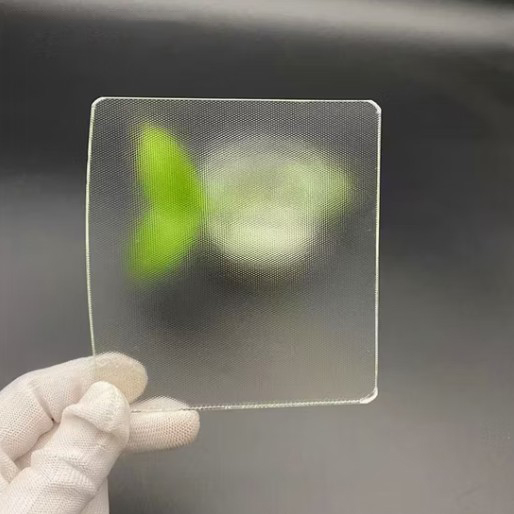

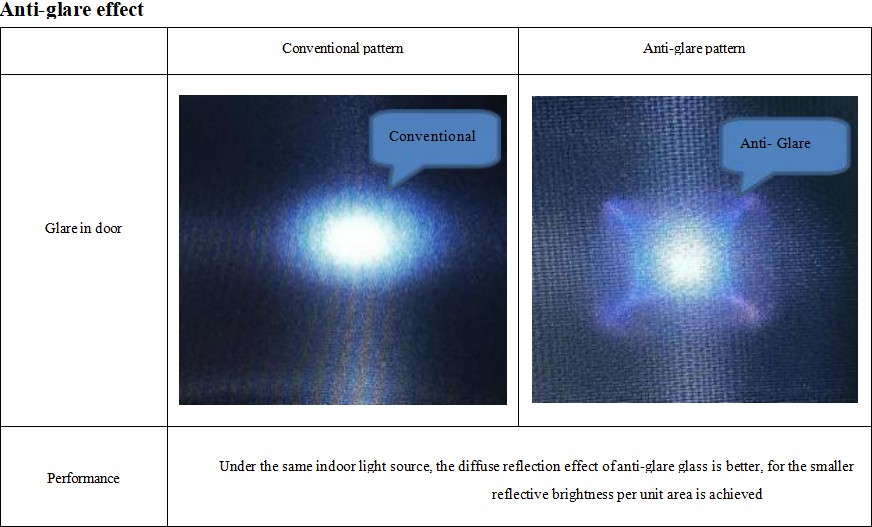

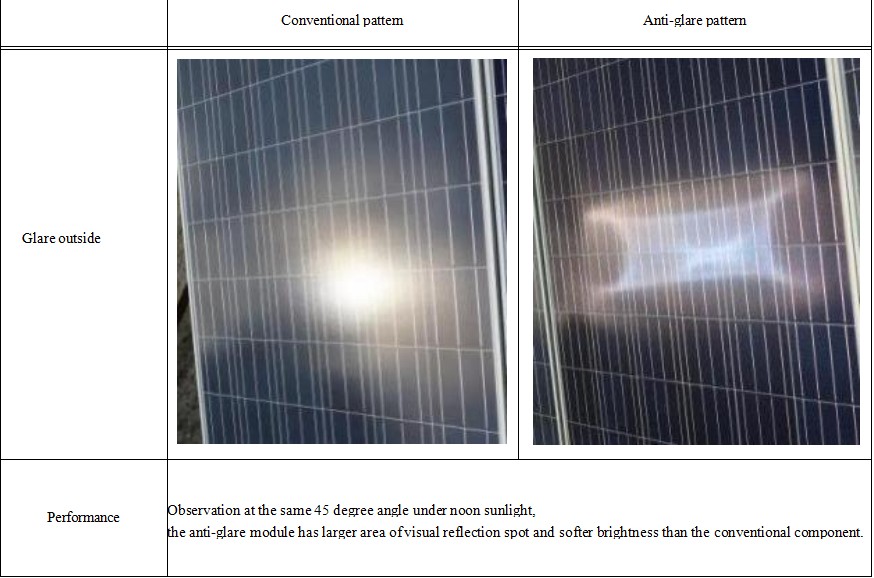

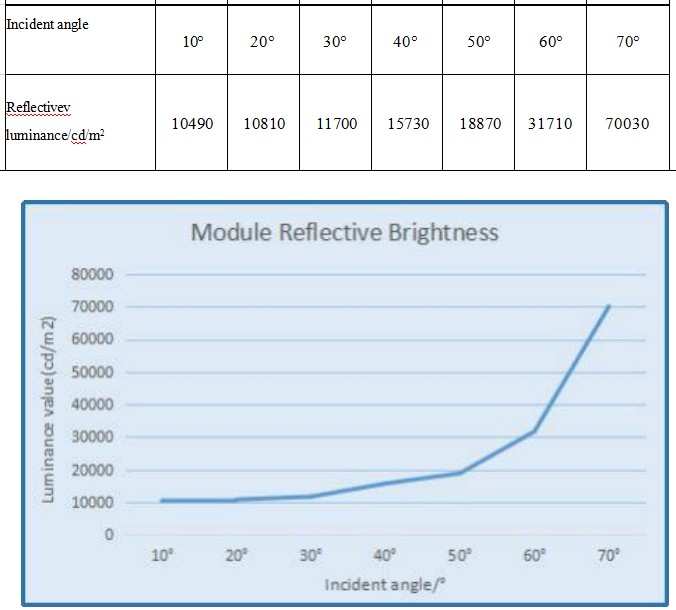

Anti-Glare (AG) Treatment / Etching

-

Process: Achieved through chemical etching (using hydrofluoric acid) or mechanical texturing of the glass surface to create a microscopically rough structure.

-

Function: Scatters reflected light diffusely rather than specularly (like a mirror). This drastically reduces glare and visual "hot spots," which is critical for installations near airports, highways, residential areas, or buildings (BIPV) to prevent light pollution and discomfort.

Self-Cleaning Coating

-

-

Process: Usually a photocatalytic coating (often Titanium Dioxide - TiO₂) applied to the external glass surface.

-

Function:

-

Photocatalytic Effect: TiO₂ reacts with UV light to break down organic dirt (bird droppings, dust, pollen).

-

Hydrophilic Effect: Makes water sheet off evenly, carrying away loosened dirt particles.

-

This minimizes soiling losses and reduces maintenance frequency, preserving optimal performance.

-

-

To get an accurate quotation, please provide (if available):

- Product dimensions & glass thickness

- Application / usage

- Edge grinding type

- Surface treatment (coating - AG/AR/AF/AM or overlay, printing, etc.)

- Packaging requirements

- Quantity or annual usage

- Required delivery time

- Drilling or special hole requirements

- Drawings or photos

If you don't have all the details yet: just provide the information you have. Our team can discuss your requirements and help you determine specifications or suggest suitable options.

-

1

1) Are you a trading company or manufacturer?

1. Leading glass deep processing factory

2. 13 years of experience

3. OEM/ODM expertise -

2

2) How to order?

1. Your detailed requirements: drawings/quantity/or your special requirements.

2. Let's get to know each other better: We can provide your requirements.

3. Email us your formal order, payment.

4. We will incorporate the order into our mass production plan and produce according to the approved sample.

5. Packing & shipping -

3

3) Do you provide samples for testing?

We can provide free samples, but the shipping cost will be borne by the customer.

-

4

4) What is your minimum order quantity?

A: 200 pieces.

-

5

5) How long does a sample order take? How about a bulk order?

Sample order: Usually within a week.

Bulk order: Usually takes 15~20 days depending on quantity and design. -

6

6) What packaging do the products use?

Plastic wrap + pearl cotton + kraft paper + cartoon box + wooden crate.

-

7

7) How do you ship the goods, and how long does it take to arrive?

We usually ship by sea / air freight/ International Express, and the arrival time depends on the distance.

-

8

8) What are your payment terms?

A: T/T 100% in advance, or other payment methods.

-

9

9) Do you provide OEM/ODM services?

Yes, we can customize.

-

9

10) Do your products have certificates?

Yes, we have ISO9001/REACH/RoSH/GS/JIS Z certifications.